335345435

Dic . 09, 2024 14:48 Back to list

china high pressure hydraulic rubber hose factory

The Evolution and Significance of China's High Pressure Hydraulic Rubber Hose Industry

The high pressure hydraulic rubber hose manufacturing sector in China has emerged as a powerhouse in the global market, reflecting the country’s rapid industrialization and technological advancement. This industry, integral to various applications in construction, mining, agriculture, and transportation, has seen remarkable growth due to increasing demand for durable and reliable hydraulic systems.

Historical Background

China's journey in rubber hose manufacturing began in the early 20th century, but it wasn't until the economic reforms in the late 1970s that the industry began to flourish. The liberalization of the economy allowed for foreign investments and modern technologies to be introduced into the sector. By the turn of the 21st century, China had positioned itself as a leading manufacturer of hydraulic hoses, surpassing many traditional suppliers in quality and production capacity.

Manufacturing Process

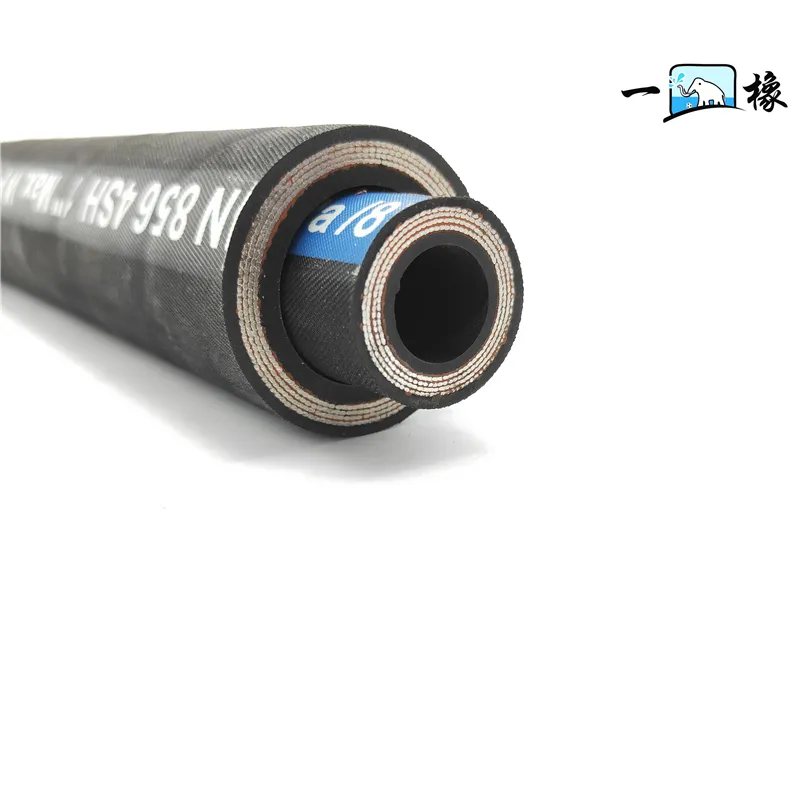

Producing high pressure hydraulic rubber hoses involves a series of meticulous steps. Initially, the rubber material is sourced and compounded with various additives to enhance its properties such as elasticity, durability, and resistance to temperature fluctuations. The formulation is critical, as it determines the hose's overall performance under extreme conditions.

The manufacturing process typically includes

1. Extrusion The compounded rubber is extruded into a tube shape, forming the inner lining of the hose. 2. Reinforcement This step involves adding layers of textiles or synthetic fibers, ensuring that the hose can withstand high pressure. Steel wire braiding or spiraling is often utilized for maximum strength. 3. Curing The hoses undergo a curing process, often in steam or hot air, which solidifies the rubber and reinforces the rubber fibers' bond. 4. Testing Each hose is subjected to rigorous testing to ensure it meets international standards for pressure rating, flexibility, and durability.

Quality Control

Quality control is a pivotal aspect of the manufacturing process. Many factories in China adhere to international standards such as ISO 9001 and SAE J517, ensuring their products are reliable and safe for use in critical applications. Continuous innovations in testing methodologies, such as hydraulic impulse testing and abrasion resistance assessments, have been adopted to guarantee superior product performance.

china high pressure hydraulic rubber hose factory

Environmental Considerations

With the prosperity of the rubber hose industry, environmental considerations have become increasingly important. Many manufacturers are now focusing on sustainable practices. They are implementing waste reduction strategies, recycling materials, and using eco-friendly rubber compounds to minimize their ecological footprint. In line with global environmental standards, factories are also upgrading their systems to reduce emissions and industrial waste.

Market Trends and Future Prospects

The demand for high pressure hydraulic rubber hoses continues to rise, driven by global industrialization. Emerging markets in Southeast Asia, Africa, and Latin America are increasingly investing in infrastructure, leading to higher consumption of hydraulic systems. Additionally, the rise of advanced machinery, such as automated construction equipment, boosts the need for robust hydraulic solutions.

Furthermore, the integration of smart technologies within hydraulic systems presents new opportunities for growth. Manufacturers are beginning to explore IoT (Internet of Things) applications, enhancing the functionality and monitoring of hydraulic systems in real-time. This technological advancement will position manufacturers in China to meet the evolving demands of the industry.

Challenges in the Industry

Despite its growth, the hydraulic hose industry in China faces several challenges. The increasing international competition, particularly from countries known for high production standards and low labor costs, poses a significant threat. Moreover, fluctuations in raw material prices and supply chain disruptions require manufacturers to adopt agile and resilient operational strategies.

Conclusion

The high pressure hydraulic rubber hose industry in China is a testament to the country’s industrial prowess. With a commitment to quality, sustainability, and innovation, Chinese manufacturers are well-positioned to maintain their dominance in the global market. As they continue to adapt to emerging technologies and market dynamics, the future looks promising for this vital sector, contributing significantly to the advancement of various industries worldwide. Through strategic investments and a focus on sustainable practices, China is not only meeting the current demands but also paving the way for future growth in the hydraulic hose manufacturing industry.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025