335345435

Dez . 10, 2024 19:52 Back to list

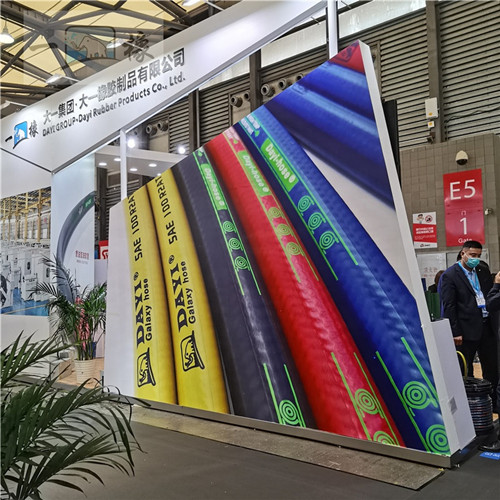

Two wire braided hydraulic hose manufacturers and their production processes explained

The Importance of Two-Wire Braided Hydraulic Hose Factories

In the industrial landscape, hydraulic hoses play a pivotal role in various applications, from construction machinery to agricultural equipment. Among the different types of hydraulic hoses, two-wire braided hydraulic hoses are known for their exceptional strength and reliability, making them a standard choice in demanding environments. This article explores the significance of two-wire braided hydraulic hose factories and their contribution to the industry.

Understanding Two-Wire Braided Hydraulic Hoses

Two-wire braided hydraulic hoses consist of an inner synthetic rubber layer that carries the hydraulic fluid, surrounded by two layers of steel wire braiding for reinforcement. This design facilitates high-pressure resistance and durability, making them well-suited for applications where high performance is crucial. The robust structure ensures that the hose can maintain its integrity under extreme conditions, such as high pressure and temperatures, which are common in hydraulic systems.

The Role of Factories in Production

The production of two-wire braided hydraulic hoses involves sophisticated manufacturing processes and quality control measures

. Factories that specialize in this segment use advanced technology and techniques to ensure that each hose meets stringent industry standards. These factories typically have dedicated facilities for research and development, allowing them to innovate and improve their products continuously.One of the primary roles of these factories is to source high-quality materials. The choice of rubber and steel wires is critical, as the performance of the hose largely depends on the materials used. For instance, high-quality synthetic rubber resists wear and oil, while strong steel wires provide the necessary tensile strength. Factories invest in procurement partnerships to ensure they have access to the best raw materials, which ultimately impacts the performance and longevity of the hoses.

Quality Control and Testing Procedures

two wire braided hydraulic hose factories

Quality control is a paramount concern in the manufacturing process of hydraulic hoses. Factories implement rigorous testing procedures to ensure that each product can withstand the pressures it will encounter in the field. This includes burst tests, tensile strength tests, and flexural tests. By adhering to international standards, such as ISO 18752 and SAE J517, factories can guarantee that their products are reliable and safe for use in various applications.

Moreover, many factories are adopting automated testing methods and data tracking systems to enhance accuracy and efficiency in their quality control processes. Through stringent testing, factories can identify potential issues early on and rectify them, ensuring that only the highest quality hoses reach the market.

Economic Impact

The presence of two-wire braided hydraulic hose factories contributes significantly to the economy. These establishments create jobs, from skilled manufacturing positions to administrative roles, and stimulate local economies through their operations. Furthermore, by supplying high-quality hoses to industries such as construction, automotive, and agriculture, these factories support the growth and efficiency of various sectors.

Environmental Considerations

In recent years, the emphasis on sustainable production methods has gained momentum. Many factories are now exploring eco-friendly materials and processes to reduce their environmental footprint. This includes recycling old hoses and using sustainable practices in raw material sourcing. By adopting green manufacturing practices, factories not only contribute to environmental preservation but also meet the growing demand from consumers and industries for sustainable products.

Conclusion

Two-wire braided hydraulic hose factories serve as a backbone for various industries by producing high-quality, reliable hydraulic hoses that withstand extreme conditions. Their commitment to quality control, innovation, and sustainability makes them crucial players in the manufacturing sector. As industries continue to evolve and demand for hydraulic solutions grows, the role of these factories will only become more significant, ensuring that they meet the rigorous challenges posed by modern applications.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025