335345435

Nov. . 06, 2024 08:34 Back to list

oem one wire braided high pressure hydraulic hose suppliers

The Rise of OEM One Wire Braided High-Pressure Hydraulic Hose Suppliers

In the world of industrial applications, the demand for durable and reliable hydraulic systems is on the rise. This has led to an increased interest in OEM (Original Equipment Manufacturer) one wire braided high-pressure hydraulic hoses. These hoses play a crucial role in the safe and efficient operation of hydraulic machinery, making them indispensable in various sectors, including construction, manufacturing, and agriculture.

Understanding One Wire Braided Hydraulic Hoses

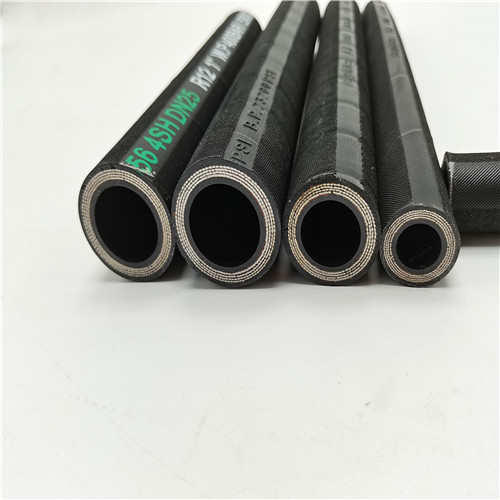

One wire braided hydraulic hoses are designed to withstand high pressures while maintaining flexibility and resistance to wear. They are typically constructed from high tensile steel wire that is braided around a rubber or thermoplastic inner core. This design allows the hose to endure extreme pressure conditions, making it suitable for heavy-duty hydraulic applications.

These hoses are often available in various sizes and specifications, ensuring that they can meet the specific requirements of different machinery. The braided steel wire reinforcement provides excellent tensile strength and resistance to external abrasions, while the inner tube is engineered to handle hydraulic fluids, oils, and other substances safely.

The Role of OEM Suppliers

OEM suppliers have become increasingly important in the hydraulic hose market. They not only produce high-quality products tailored to specific machinery but also focus on ensuring reliability and performance under extreme conditions. By collaborating closely with equipment manufacturers, OEM suppliers can develop hydraulic hoses that meet the exact specifications required for various applications.

Working with OEM suppliers means that companies can benefit from products that are designed to operate seamlessly with their existing equipment. This is particularly crucial for businesses that rely on heavy machinery for daily operations, as any malfunction can lead to downtime and significant financial losses.

oem one wire braided high pressure hydraulic hose suppliers

Benefits of Choosing OEM One Wire Braided Hoses

1. Quality Assurance OEM suppliers adhere to strict manufacturing standards, ensuring that their products are of the highest quality. This commitment to quality minimizes the risks associated with hydraulic failures.

2. Customization Many OEM suppliers offer customization options, allowing companies to order hoses that meet their unique specifications. This tailored approach can improve the efficiency and performance of hydraulic systems.

3. Longer Lifespan Quality manufacturing and materials used in OEM hoses result in a longer lifespan, reducing the need for frequent replacements and saving costs in the long run.

4. Support and Expertise OEM suppliers often provide technical support and expertise, helping customers select the right hydraulic hose for their specific applications and offering guidance on installation and maintenance.

Conclusion

As businesses continue to seek reliable hydraulic solutions, the importance of OEM one wire braided high-pressure hydraulic hose suppliers cannot be overstated. Their commitment to quality, customization, and support ensures that industries can operate efficiently and safely. By investing in high-quality hoses from reputable OEM suppliers, companies can enhance the performance of their hydraulic systems, reduce downtime, and ultimately improve their bottom line. The growth of this sector reflects the ongoing advancements in hydraulic technology and the increasing demand for reliable industrial equipment, making it a key player in the future of hydraulic applications.

-

High-Quality Distribution PTFE Hose for Industrial Flexibility

NewsJul.23,2025

-

Durable Pressure Washer Rubber Hose for Hot Water & High Flexibility

NewsJul.22,2025

-

Twin Hydraulic Hose for Efficient Fluid Transfer | Durable & Flexible

NewsJul.22,2025

-

Twin Hydraulic Hose | High Pressure & Durable

NewsJul.21,2025

-

Discount Hydraulic Hose Factories | Top Quality & Discounts

NewsJul.20,2025

-

EN856 4SP Hydraulic Hose - High Pressure & Durable

NewsJul.20,2025