335345435

Okt . 11, 2024 02:07 Back to list

OEM Hydraulic Hose Crimping Machines from Leading Manufacturers and Suppliers Worldwide

An Insight into OEM Hydraulic Hose Crimping Machine Factories

In today's industrial landscape, the demand for precision and reliability has led to an increased interest in hydraulic systems. A key component of these systems is the hydraulic hose, which requires accurate crimping to ensure optimal performance and safety. OEM (Original Equipment Manufacturer) hydraulic hose crimping machines play a crucial role in this process. This article explores the vital aspects of OEM hydraulic hose crimping machine factories, their significance, and the technology that propels them.

Understanding Hydraulic Hose Crimping

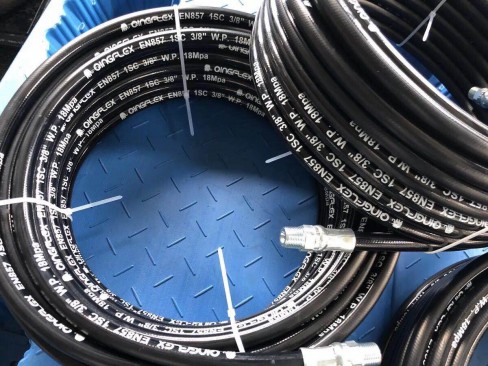

Crimping refers to the process of deforming a metal connector in such a way that it securely attaches to the hydraulic hose. This connection must withstand high pressures, making the quality of crimping particularly important. An effective crimping machine guarantees a consistent and durable connection, ensuring that the entire hydraulic system operates efficiently and safely. OEM hydraulic hose crimping machines are designed specifically for this purpose, often characterized by their high quality, precision engineering, and advanced technology.

Role of OEM Factories

OEM factories specialize in manufacturing components and machinery that meet specific requirements set by businesses. In the case of hydraulic hose crimping machines, these factories employ expert engineers proficient in hydraulic design and machine technology. They focus on creating machines that not only meet industry standards but also cater to the unique needs of their clients. This customization capability sets OEM manufacturers apart from generic machine builders.

One of the primary advantages of sourcing hydraulic hose crimping machines from OEM factories is the assurance of quality. These manufacturers are held to stringent quality control measures that guarantee the machines conform to international industry standards. Moreover, many OEM factories offer warranties and post-sale support, ensuring that clients receive assistance even after purchase.

Technological Innovations in Crimping Machines

Technology has revolutionized the manufacturing of hydraulic hose crimping machines. Modern OEM factories integrate advanced technology into their production lines, leading to improved performance and efficiency. Notable innovations include

oem hydraulic hose crimping machine factories

1. Computer Numerical Control (CNC) Systems These systems provide automatic adjustments to the crimping process, ensuring precision and consistency. CNC technology minimizes human error, which is crucial in high-pressure applications.

2. Interactive Control Panels Many contemporary crimping machines come equipped with user-friendly interfaces that allow operators to easily set parameters, monitor performance, and troubleshoot any issues in real time.

3. Data Analytics Advanced machines can collect data during the crimping process, enabling manufacturers to analyze performance trends, identify potential issues, and refine their processes for better efficiency.

4. Modular Design OEM factories are increasingly adopting modular designs for their machines, allowing customization and the ability to easily upgrade components as technology evolves or as user needs change.

The Future of OEM Hydraulic Hose Crimping Machines

As industries continue to evolve, the demand for high-quality hydraulic systems is expected to grow. This translates into a corresponding increase in the need for reliable hydraulic hose crimping machines. OEM factories will play a critical role in fulfilling this demand by adopting newer technologies, enhancing production methods, and extending their product offerings.

Moreover, as companies worldwide focus on sustainability, OEM manufacturers will likely explore eco-friendly materials and energy-efficient designs in their hydraulic hose crimping machines. This shift not only aligns with global trends but also opens new opportunities for market growth.

Conclusion

OEM hydraulic hose crimping machine factories are essential players in the hydraulic industry, providing the technology and expertise needed to ensure safe and efficient hydraulic systems. Their commitment to quality, innovative design, and customization makes them invaluable partners in the manufacturing process. As technology continues to advance, these factories will undoubtedly adapt and evolve, meeting the ever-changing demands of the marketplace while ensuring that industries operate smoothly and effectively.

-

High-Quality Distribution PTFE Hose for Industrial Flexibility

NewsJul.23,2025

-

Durable Pressure Washer Rubber Hose for Hot Water & High Flexibility

NewsJul.22,2025

-

Twin Hydraulic Hose for Efficient Fluid Transfer | Durable & Flexible

NewsJul.22,2025

-

Twin Hydraulic Hose | High Pressure & Durable

NewsJul.21,2025

-

Discount Hydraulic Hose Factories | Top Quality & Discounts

NewsJul.20,2025

-

EN856 4SP Hydraulic Hose - High Pressure & Durable

NewsJul.20,2025