335345435

Dez . 23, 2024 06:08 Back to list

Hydraulic Pipe Standards and Specifications for Various Applications and Industries

Understanding Hydraulic Pipe Specifications

Hydraulic systems are indispensable in various industries, including construction, manufacturing, and automotive, due to their efficiency and power. One vital component of these systems is hydraulic pipes, which are designed to transport fluids under pressure. To ensure safety, reliability, and performance, it is crucial to adhere to specific hydraulic pipe specifications. This article will delve into the key aspects of hydraulic pipe specifications, including materials, dimensions, pressure ratings, and applications.

Materials Used in Hydraulic Pipes

Hydraulic pipes are typically made from various materials, including steel, stainless steel, aluminum, and plastic. The choice of material directly affects the pipe’s strength, durability, corrosion resistance, and weight.

- Steel Pipes These are among the most common types used due to their high strength and ability to withstand high pressures. Steel pipes can also be coated to prevent corrosion, extending their service life. - Stainless Steel Pipes While more expensive, stainless steel pipes offer excellent resistance to corrosion, making them ideal for hydraulic systems that may be exposed to harsh environments. - Aluminum Pipes Known for being lightweight, aluminum pipes are easier to handle and install. However, they may not be suitable for very high-pressure applications. - Plastic Pipes Used in low-pressure applications, plastic pipes are lightweight and resistant to corrosion but offer lower strength compared to metal pipes.

Dimensions and Standards

The specifications for hydraulic pipes include various dimensions, such as diameter and wall thickness

. These dimensions are crucial as they determine the flow rate and pressure resistance of the pipes.Industry standards, such as those set by the American National Standards Institute (ANSI) or the International Organization for Standardization (ISO), specify the acceptable dimensions and tolerances for hydraulic pipes. For example, the ANSI/ASME B36.10 standard outlines the dimensions for welded and seamless steel pipes. Manufacturers must comply with these standards to ensure compatibility and interoperability between different components of hydraulic systems.

hydraulic pipe specification pdf

Pressure Ratings

One of the most critical factors in hydraulic pipe specifications is the pressure rating. This rating indicates how much internal pressure a pipe can safely handle without failing. Pressure ratings are typically measured in pounds per square inch (psi) or bar.

Hydraulic pipes are often classified into different pressure ratings, such as low, medium, and high pressure. For example, low-pressure hydraulic pipes may withstand up to 150 psi, while high-pressure pipes can handle over 5,000 psi. It’s essential to select a pipe with a pressure rating that exceeds the maximum operating pressure of the hydraulic system to ensure safety and functionality.

Applications of Hydraulic Pipes

Hydraulic pipes are used in a wide array of applications, including

- Construction Equipment Hydraulic pipes are commonly found in excavators, bulldozers, and cranes, where they power hydraulic cylinders that lift and move heavy loads. - Manufacturing Machinery In factories, hydraulic pipes are essential for operating presses, injection molding machines, and automated assembly systems. - Automotive Systems Hydraulic pipes are integral to brake systems, power steering, and hydraulic lifts, enabling precise control and movement. - Aerospace In aircraft, hydraulic pipes play a crucial role in flight control systems, landing gear operations, and other critical functions.

Conclusion

Hydraulic pipe specifications are a fundamental component of hydraulic systems, ensuring they operate safely and efficiently. Understanding the materials, dimensions, pressure ratings, and various applications of hydraulic pipes allows engineers and technicians to make informed decisions when designing and maintaining hydraulic systems. By adhering to established specifications, industries can enhance the performance and longevity of their hydraulic installations, ultimately leading to safer and more productive operations. Whether in construction, manufacturing, or any other field, the importance of proper hydraulic pipe specifications cannot be overstated.

-

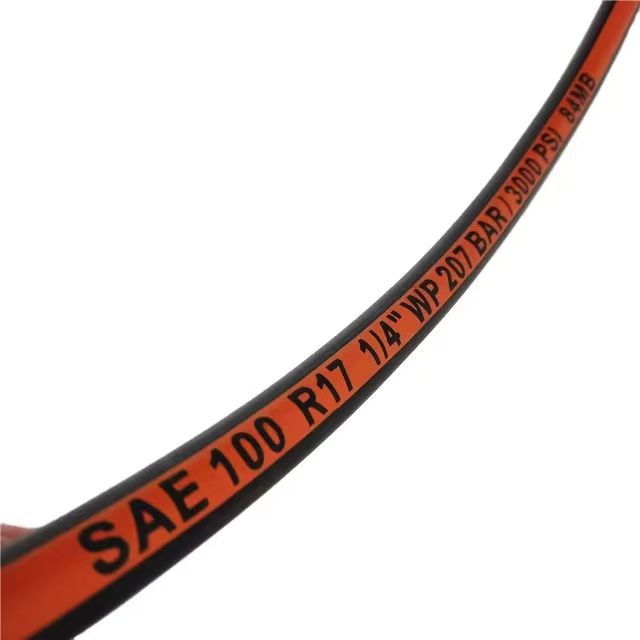

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025