335345435

Dez . 24, 2024 10:36 Back to list

Exploring the Benefits and Applications of Flat Hydraulic Fittings in Modern Engineering

The Rise of Flat Hydraulic Fittings An In-Depth Look

In the world of hydraulic systems, the importance of effective and reliable fittings cannot be overstated. Among various types of fittings, flat hydraulic fittings have gained significant traction in recent years. These innovative components offer numerous advantages, aligning themselves perfectly with the evolving demands of modern industries. This article delves into the characteristics, advantages, and applications of flat hydraulic fittings, providing a comprehensive overview for professionals and enthusiasts alike.

Understanding Flat Hydraulic Fittings

Flat hydraulic fittings are designed to facilitate the connection between hydraulic hoses and equipment in a hydraulic system. Unlike traditional fittings, which often feature round connectors, flat hydraulic fittings boast a unique flat design that promotes a more efficient seal and better fluid flow. The streamlined construction of these fittings minimizes turbulence and pressure drops, making them an ideal choice for high-performance hydraulic applications.

Advantages of Flat Hydraulic Fittings

1. Improved Sealing Mechanism One of the primary benefits of flat hydraulic fittings is their superior sealing capabilities. The flat surfaces allow for better contact and, consequently, a more secure seal. This reduces the likelihood of leaks, which can lead to performance losses and potential safety hazards.

2. Space Efficiency The flat design of these fittings allows for a more compact arrangement in hydraulic systems. This is particularly beneficial in applications where space is limited, as it can lead to more straightforward installations without compromising performance.

3. Reduced Weight Flat fittings are generally lighter than their traditional counterparts. The weight reduction can contribute to improved energy efficiency, particularly in mobile applications, such as construction machinery and automotive systems. Lighter components also enhance the overall maneuverability of the machinery.

4. Enhanced Versatility Flat hydraulic fittings are designed to accommodate various hose sizes and configurations, making them suitable for a wide range of hydraulic applications. Their adaptability to different settings allows manufacturers to streamline operations and reduce inventory costs.

5. Resistance to Corrosion and Wear Most flat hydraulic fittings are made from high-quality materials that are resistant to corrosion, wear, and fatigue. This durability ensures a longer lifespan, which ultimately translates into lower maintenance costs and increased reliability.

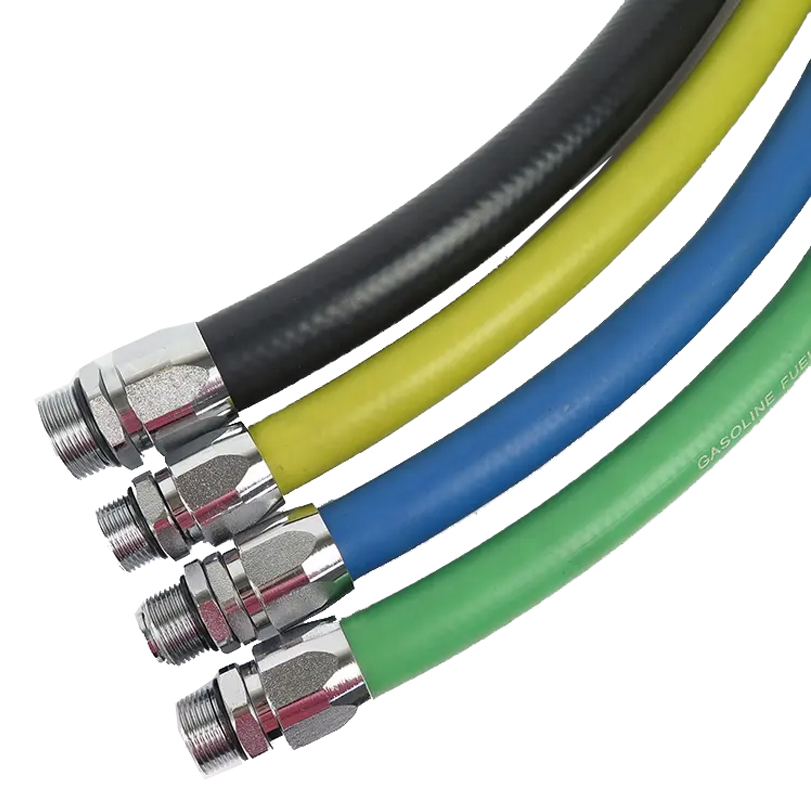

flat hydraulic fittings

Applications in Various Industries

Flat hydraulic fittings are being utilized across multiple industries, demonstrating their versatility and efficiency

- Construction and Heavy Machinery In heavy-duty machinery utilized at construction sites, flat hydraulic fittings are crucial for reliable performance. They help in sustaining the high pressure needed for hydraulic lifts and excavators, ensuring safety and efficiency in operations.

- Automotive Industry With the increasing trend towards compact and lightweight automotive designs, flat hydraulic fittings are now more prevalent in modern vehicles. They are often used in brake lines, power steering, and various other hydraulic systems, contributing to overall vehicle performance.

- Manufacturing and Automation In automated manufacturing environments, where precision and reliability are essential, flat hydraulic fittings facilitate the operation of robotics and automated machinery. Their ability to provide consistent pressure and flow makes them ideal for processes such as stamping, welding, and assembly.

- Marine Applications The marine industry is also seeing a rise in the adoption of flat hydraulic fittings due to their resistance to corrosion and ability to handle varying pressures. They are used in hydraulic steering systems and other critical applications.

Conclusion

As industries continue to evolve, the demand for efficient and reliable hydraulic systems becomes paramount. Flat hydraulic fittings stand out as a leading solution that combines innovative design with essential functionality. Their ability to enhance sealing mechanisms, save space, reduce weight, and offer versatility makes them an attractive choice for various applications.

Moving forward, as technological advancements continue to advance hydraulic engineering, we can expect flat hydraulic fittings to play an even more significant role in shaping the future of hydraulic systems across multiple industries. Whether in construction, automotive, manufacturing, or marine settings, their relevance and application are likely to expand, underscoring the importance of investing in quality hydraulic components.

-

Industrial Distribution PTFE Hose - High Purity & Flexibility

NewsJul.31,2025

-

Durable Twin Hydraulic Hose for High-Pressure Systems

NewsJul.31,2025

-

Discount Hydraulic Hose Factories – Bulk Supply & Quality Assurance

NewsJul.30,2025

-

Hydraulic Hose Crimping Machine for Precise & Durable Connections

NewsJul.29,2025

-

High Pressure 4SH Hydraulic Hose for Heavy Duty Applications

NewsJul.29,2025

-

Hydraulic Hose Wholesale – Custom Pressure Hoses & Fast Supply

NewsJul.29,2025