335345435

sep . 28, 2024 19:02 Back to list

Leading Manufacturer of High-Quality Hydraulic Hose Assemblies for Various Industries

The Essential Role of Hydraulic Hose Assembly Manufacturers

Hydraulic systems are integral to many industrial and mobile applications, providing the necessary power to drive machinery, lift heavy loads, and facilitate various processes that involve fluid movement. At the heart of these systems lies the hydraulic hose assembly, a critical component that ensures efficient fluid transfer. Hydraulic hose assembly manufacturers play a vital role in this sector, crafting high-quality, durable hoses that meet the diverse needs of different applications.

Understanding Hydraulic Hose Assemblies

Hydraulic hose assemblies are comprised of three primary components the hose itself, the fittings that connect the hose to the system, and the appropriate adapters. The hoses are typically made from a blend of synthetic rubber, steel, and other materials designed to withstand high pressures and temperatures. The fittings and adapters are essential for ensuring a secure and leak-free connection to the hydraulic system.

In hydraulic systems, hoses must endure extreme conditions, including high fluid pressures, fluctuating temperatures, and exposure to various chemicals. This demanding environment necessitates that manufacturers adhere to stringent industry standards and quality controls. As such, hydraulic hose assembly manufacturers invest heavily in research, development, and testing to produce hoses that are reliable and long-lasting.

Types of Hydraulic Hoses

There are various types of hydraulic hoses, each designed for specific applications and performance requirements. The most common types include

1. Wire-Braided Hoses These are reinforced with layers of steel wire to provide strength and durability. They are ideal for high-pressure applications and are commonly used in construction and heavy machinery.

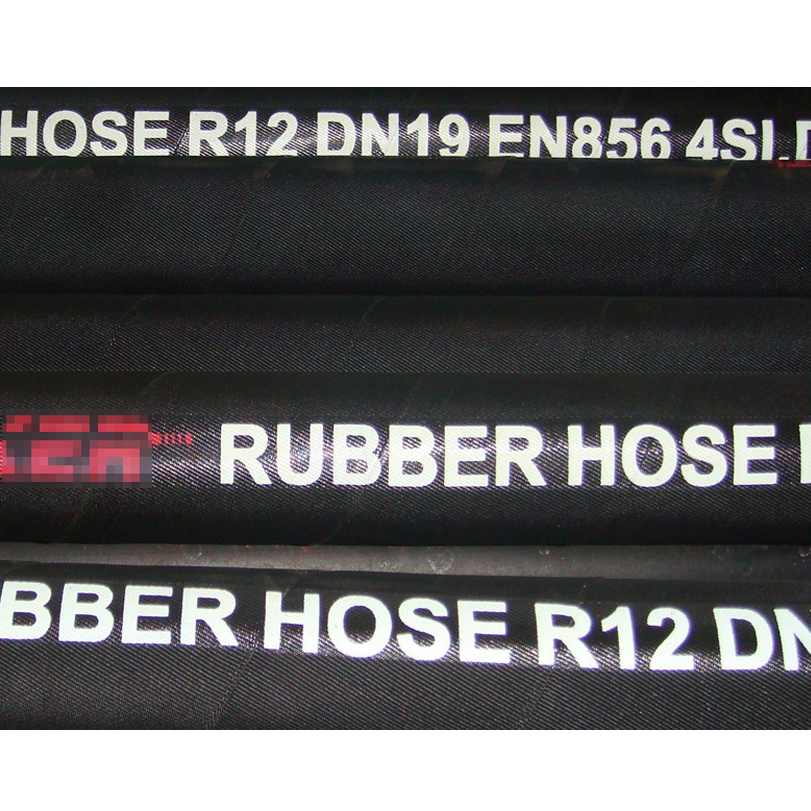

2. Spiral-Wound Hoses Spiral hoses are designed for even greater strength, using multiple layers of wire wound in a spiral configuration. They can handle extremely high pressures and are often used in industrial applications.

3. Thermoplastic Hoses Made from synthetic materials, these hoses offer excellent flexibility and resistance to chemical degradation. They are often used in mobile equipment and applications where weight is a concern.

Each type of hose comes with its own set of advantages and is chosen based on the specific requirements of the hydraulic system in which it will be used.

hydraulic hose assembly manufacturer

The Manufacturing Process

The manufacturing process of hydraulic hose assemblies is complex and involves several critical steps

1. Material Selection The first step is selecting high-quality materials that can withstand the specific demands of the intended application.

2. Hose Construction The hose is constructed by layering the chosen materials, including the inner tube, reinforcement layers, and outer cover. Each layer serves a specific purpose, from maintaining pressure to protecting against environmental damage.

3. Fitting and Assembly Once the hose is constructed, fittings are attached. This is a meticulous process that requires precision to ensure a secure connection. Manufacturers utilize specialized machinery and trained technicians to perform this assembly.

4. Testing After assembly, the hoses are subjected to rigorous testing. This includes pressure testing, flexibility assessment, and evaluation for leaks. Only those hoses that pass these tests will be deemed ready for shipment.

5. Quality Assurance Finally, manufacturers implement quality assurance processes to ensure that all products meet industry standards and customer specifications. This includes certifications such as ISO and SAE, which guarantee that the hoses are suitable for use in their respective applications.

Conclusion

Hydraulic hose assembly manufacturers are fundamental to the functionality of hydraulic systems across various industries. Their commitment to quality, innovation, and customer service ensures that businesses receive reliable products that can withstand the rigors of demanding environments. As technology continues to evolve, manufacturers will need to adapt and advance their processes to meet the changing needs of the market, particularly with the rise of new materials and designs.

In summary, investing in high-quality hydraulic hose assemblies from reputable manufacturers is crucial for any industry reliant on hydraulic systems. These components are not merely pipes; they are vital lifelines that help power the machinery and processes that drive our modern economy.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025