335345435

dec . 12, 2024 09:58 Back to list

hydraulic fittings catalogue pdf

Understanding Hydraulic Fittings A Comprehensive Overview

Hydraulic fittings are crucial components used in hydraulic systems to connect hoses, pipes, and tubes efficiently. Their primary function is to facilitate the transfer of hydraulic fluid between different parts of a hydraulic system, ensuring the system operates smoothly and effectively. This article delves into the various aspects of hydraulic fittings, their types, applications, and importance in modern engineering.

The Role of Hydraulic Fittings

At the heart of any hydraulic system lies the need for secure and leak-free connections. Hydraulic fittings play an integral role in achieving this. They ensure that fluid can flow from one component to another without losing pressure or volume, which is vital for the reliability of the entire system. If a fitting were to fail, it could lead to significant losses in efficiency, potential damage to components, or even hazardous leaks. Thus, the design and selection of hydraulic fittings must be approached with careful consideration.

Types of Hydraulic Fittings

Hydraulic fittings come in various shapes, sizes, and configurations, each tailored for specific applications. Here are some common types

1. Elbow Fittings These fittings are designed to change the direction of fluid flow. They are typically available in 45-degree and 90-degree angles and are essential for navigating tight spaces in machinery.

2. Tee Fittings Used when a fluid line needs to branch out to two paths, tee fittings allow for a smooth transition without compromising flow rates.

3. Couplings These are used to connect two hoses or pipes. Couplings are critical for maintenance, enabling sections of the hydraulic system to be easily disconnected and reconnected.

4. Adapters Adapters are necessary when different types of connections are involved. They allow for compatibility between fittings of varying sizes and styles.

5. Caps and Plugs These fittings are essential for sealing off ends of pipes or hoses when they are not in use or during maintenance.

Materials Used in Hydraulic Fittings

The choice of materials for hydraulic fittings significantly influences their performance and longevity. Common materials include

- Steel Known for its strength and durability, steel is a popular choice for high-pressure applications

. It can resist wear and is less likely to deform under pressure.hydraulic fittings catalogue pdf

- Stainless Steel This material offers excellent corrosion resistance, making it suitable for environments where moisture and aggressive fluids are present.

- Brass Often used for lower-pressure applications, brass fittings are easy to machine and provide decent resistance to corrosion.

- Plastic In specific scenarios where weight and resistance to corrosion are crucial, plastic fittings can be a viable option, although usually reserved for lower-pressure applications.

Applications of Hydraulic Fittings

Hydraulic fittings are found across a broad spectrum of industries

- Manufacturing In hydraulic presses and machinery, fittings ensure that hydraulic fluid is efficiently delivered to perform tasks such as molding or shaping materials.

- Construction Excavators, cranes, and bulldozers rely heavily on hydraulic systems, where fittings are vital for the movement and function of hydraulic cylinders.

- Automotive The automotive industry utilizes hydraulic fittings in braking systems, power steering, and various other systems requiring fluid transfer.

- Agriculture Equipment such as tractors and combines depend on hydraulic fittings for operating attachments and performing essential functions.

Importance of Proper Selection

The selection of the right hydraulic fitting is paramount. Factors such as pressure ratings, fluid compatibility, temperature ranges, and connection types must be taken into account. Using an inappropriate fitting can lead to failures, leaks, and potential accidents. Therefore, professionals working with hydraulic systems must consult manufacturers' catalogs and technical specifications to ensure the correct choices are made.

Conclusion

Hydraulic fittings, though often overlooked, are vital components in any hydraulic system. Their ability to create secure, leak-free connections is fundamental to the efficiency and safety of machinery across many industries. Understanding the various types of fittings, materials, and their applications allows engineers and technicians to make informed decisions that enhance the performance and reliability of hydraulic systems. Investing time in selecting the right hydraulic fittings ultimately leads to increased operational efficiency and reduced maintenance costs, underscoring their importance in modern technological applications.

-

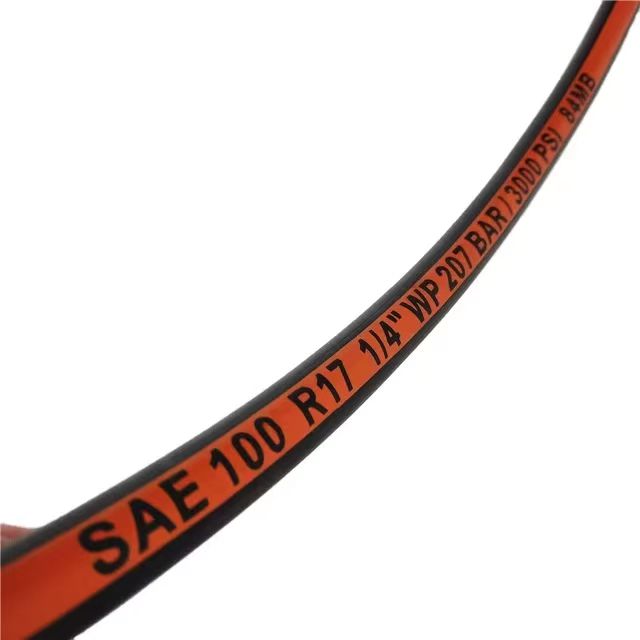

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025