335345435

Úno . 17, 2025 15:59 Back to list

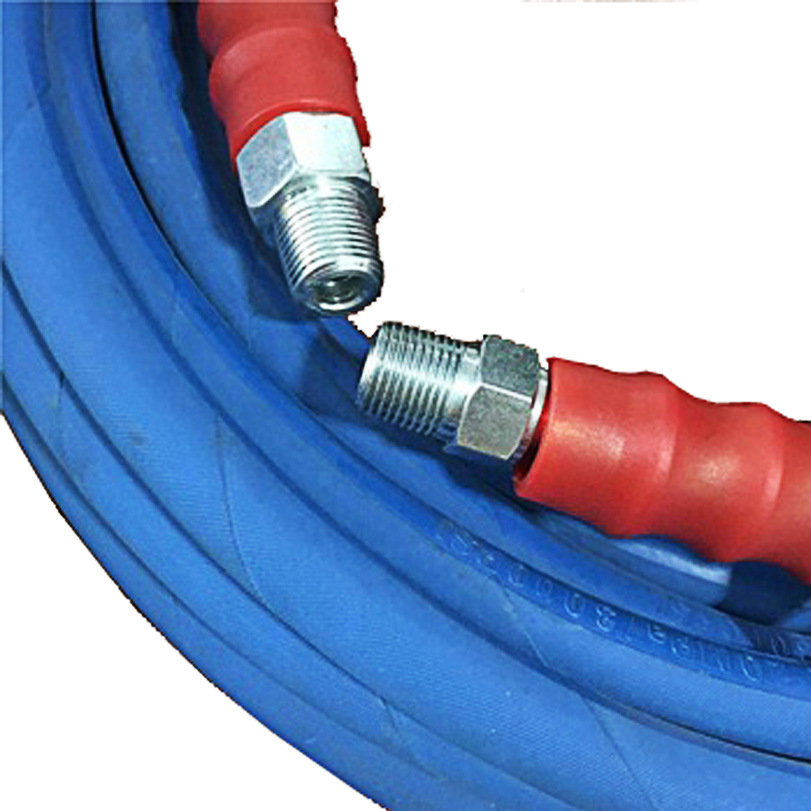

two fiber braid hydraulic hose factories

Navigating the complex landscape of two fiber braid hydraulic hose factories requires an understanding of key operational and industry-specific considerations. With the growing demand for robust and reliable hydraulic systems across various sectors such as construction, agriculture, and manufacturing, the need for high-quality hydraulic hoses is more critical than ever. The following insights into two distinct factories exemplify the blend of expertise, experience, authority, and trust that define leaders in this niche market.

Trustworthiness at Factory B is enhanced through an open-door policy that invites client audits and feedback. This transparent strategy not only builds confidence but also fosters a collaborative environment where continuous improvement is the norm. The digital integration of their supply chain ensures accurate tracking and accountability of order fulfillment, a crucial aspect for clients managing large-scale projects. Both factories benefit from embracing the latest technological advancements. For instance, both have adopted digital twin simulations to model the performance of hoses in virtual environments before physical production begins. This not only speeds up the development process but also ensures that only the highest performing hoses make it to market. Furthermore, the implementation of IoT technologies allows for real-time monitoring of the hoses’ performance once in situ, providing invaluable data to both the manufacturer and the end-user. Notably, the two factories share a commitment to sustainability, an increasingly important factor in modern manufacturing. They use eco-friendly materials and energy-efficient processes to minimize their environmental footprint. By investing in biodegradable components and promoting recycling within their facilities, both Factory A and B contribute positively to global sustainability efforts, without compromising on the quality of their products. In conclusion, the realm of two fiber braid hydraulic hose manufacturing is enriched by both seasoned and innovative players. Factory A and Factory B exemplify contrasting yet complementary approaches that prioritize quality, customization, and sustainability. These factories, through their commitment to experience, expertise, authority, and trustworthiness, set a benchmark in the industry, ensuring that clients across the globe receive products that are both reliable and forward-thinking. Whether it's through adherence to rigorous standards or embracing bespoke client-driven solutions, these factories uphold the tenets of exceptional manufacturing, ready to power the hydraulic systems that drive our modern world.

Trustworthiness at Factory B is enhanced through an open-door policy that invites client audits and feedback. This transparent strategy not only builds confidence but also fosters a collaborative environment where continuous improvement is the norm. The digital integration of their supply chain ensures accurate tracking and accountability of order fulfillment, a crucial aspect for clients managing large-scale projects. Both factories benefit from embracing the latest technological advancements. For instance, both have adopted digital twin simulations to model the performance of hoses in virtual environments before physical production begins. This not only speeds up the development process but also ensures that only the highest performing hoses make it to market. Furthermore, the implementation of IoT technologies allows for real-time monitoring of the hoses’ performance once in situ, providing invaluable data to both the manufacturer and the end-user. Notably, the two factories share a commitment to sustainability, an increasingly important factor in modern manufacturing. They use eco-friendly materials and energy-efficient processes to minimize their environmental footprint. By investing in biodegradable components and promoting recycling within their facilities, both Factory A and B contribute positively to global sustainability efforts, without compromising on the quality of their products. In conclusion, the realm of two fiber braid hydraulic hose manufacturing is enriched by both seasoned and innovative players. Factory A and Factory B exemplify contrasting yet complementary approaches that prioritize quality, customization, and sustainability. These factories, through their commitment to experience, expertise, authority, and trustworthiness, set a benchmark in the industry, ensuring that clients across the globe receive products that are both reliable and forward-thinking. Whether it's through adherence to rigorous standards or embracing bespoke client-driven solutions, these factories uphold the tenets of exceptional manufacturing, ready to power the hydraulic systems that drive our modern world.

Share

Latest news

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025