335345435

Zář . 21, 2024 17:57 Back to list

thermoplastic high pressure hose

Understanding Thermoplastic High Pressure Hose A Comprehensive Overview

Thermoplastic high pressure hoses are essential components in various industrial applications, renowned for their durability, flexibility, and resistance to extreme conditions. Unlike traditional rubber hoses, these thermoplastic variants are designed to withstand not just high pressures, but also a wide array of chemicals and environmental factors, making them ideal for everything from hydraulic systems to pneumatic tools.

One of the primary advantages of thermoplastic high pressure hoses is their lightweight nature. This feature significantly reduces the overall weight of equipment, enhancing maneuverability and ease of use. Industries that rely on heavy machinery, such as construction and manufacturing, benefit from this reduced weight, as it allows for better handling and decreased operator fatigue.

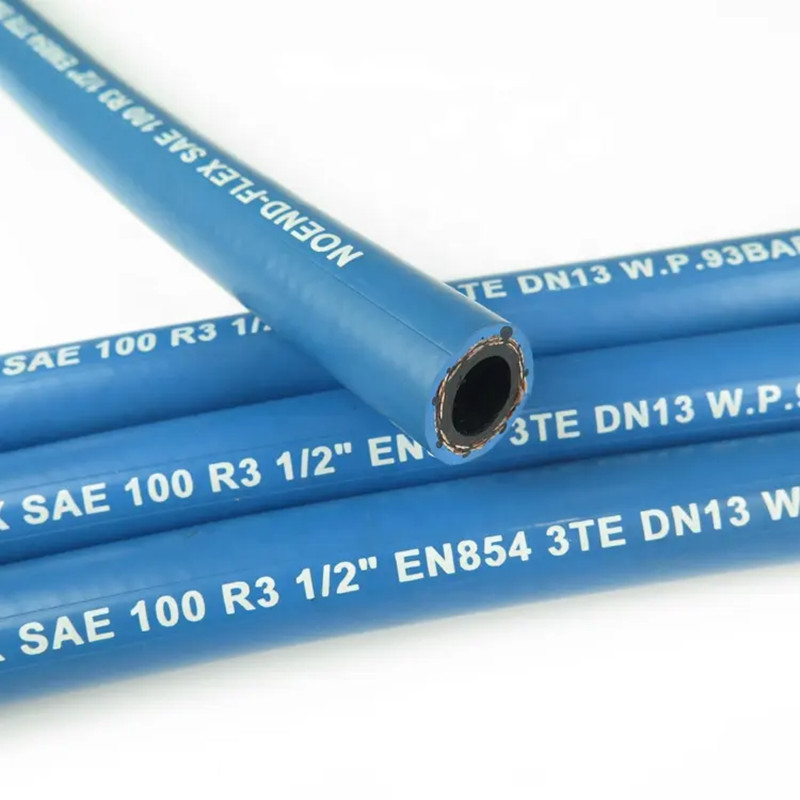

The construction of thermoplastic high pressure hoses typically involves multiple layers

. The inner layer is made of high-quality thermoplastic materials, while additional layers provide reinforcement, often featuring synthetic fibers or steel wire. This multi-layer design not only contributes to the hose's strength but also enhances its flexibility, allowing for tight bends and routing in confined spaces without the risk of kinking or collapsing.thermoplastic high pressure hose

Another noteworthy property of thermoplastic hoses is their resistance to abrasion and external damage. Many thermoplastic formulations are designed to resist weathering, UV exposure, and other harsh environmental contaminants. This inherent resilience results in a longer service life, reducing the frequency and costs associated with replacements. Additionally, many thermoplastic hoses maintain their integrity in varying temperature ranges, adding to their versatility in different working environments.

Moreover, the ease of maintenance and cleaning is a significant factor for users. Thermoplastic materials can often be cleaned with common solvents and detergents, ensuring compliance with hygiene standards, especially in food processing and pharmaceutical applications. The non-porous nature of these hoses also minimizes the risk of contamination.

In terms of application versatility, thermoplastic high pressure hoses are employed in numerous sectors, including automotive, agricultural, and chemical processing. Their ability to handle fluids, air, and even certain gases with efficiency makes them indispensable for hydraulic machinery, sprayers, and pneumatic systems.

In conclusion, thermoplastic high pressure hoses present a robust and flexible solution for high-pressure applications across various industries. Their lightweight design, durability, resistance to environmental factors, and ease of maintenance make them a preferred choice for both manufacturers and end-users. As technology continues to evolve, we can anticipate even more innovative developments in thermoplastic hose construction and functionality, further enhancing their role in modern industrial applications.

-

High-Quality Distribution PTFE Hose for Industrial Flexibility

NewsJul.23,2025

-

Durable Pressure Washer Rubber Hose for Hot Water & High Flexibility

NewsJul.22,2025

-

Twin Hydraulic Hose for Efficient Fluid Transfer | Durable & Flexible

NewsJul.22,2025

-

Twin Hydraulic Hose | High Pressure & Durable

NewsJul.21,2025

-

Discount Hydraulic Hose Factories | Top Quality & Discounts

NewsJul.20,2025

-

EN856 4SP Hydraulic Hose - High Pressure & Durable

NewsJul.20,2025