335345435

Pro . 31, 2024 17:51 Back to list

Top Manufacturers of Flexible PTFE Hose Pipes for Various Applications

The Role of PTFE Flexible Hose Pipe Manufacturers in Industrial Applications

Polytetrafluoroethylene (PTFE) flexible hose pipes have emerged as vital components in various industrial applications due to their unique properties and versatility. Manufactured from a high-performance fluoropolymer, PTFE exhibits outstanding chemical resistance, high temperature tolerance, and flexibility, making it the preferred choice for industries that require robust and reliable piping solutions. The manufacturers of PTFE flexible hose pipes play a critical role in ensuring the quality and performance of these products, catering to a wide range of needs across different sectors.

Understanding PTFE Hose Pipes

PTFE hose pipes are often characterized by their smooth inner surface, which minimizes friction and enhances flow rates. These hoses can operate efficiently at temperatures ranging from -100°F to 500°F (-73°C to 260°C) and can withstand high pressures, making them ideal for conveying aggressive chemicals and fluids. The non-stick properties of PTFE also mean that these hoses do not easily corrode or degrade, ensuring longevity and reducing maintenance costs.

Key Applications

PTFE flexible hoses are extensively used in various industries, including pharmaceuticals, food processing, aerospace, and semiconductor manufacturing. In the pharmaceutical industry, these hoses are critical for transporting sterile liquids and gases, as they can be easily cleaned and prevent contamination. Within the food processing field, PTFE hoses ensure that the integrity of food products is maintained, as they can be sanitized effectively.

In aerospace applications, the lightweight and heat-resistant characteristics of PTFE flexible hoses are invaluable for fuel delivery systems and hydraulic applications. Similarly, semiconductor manufacturing relies on PTFE hoses for the transportation of chemical substances used in the production processes, where purity and chemical compatibility are paramount.

The Manufacturing Process

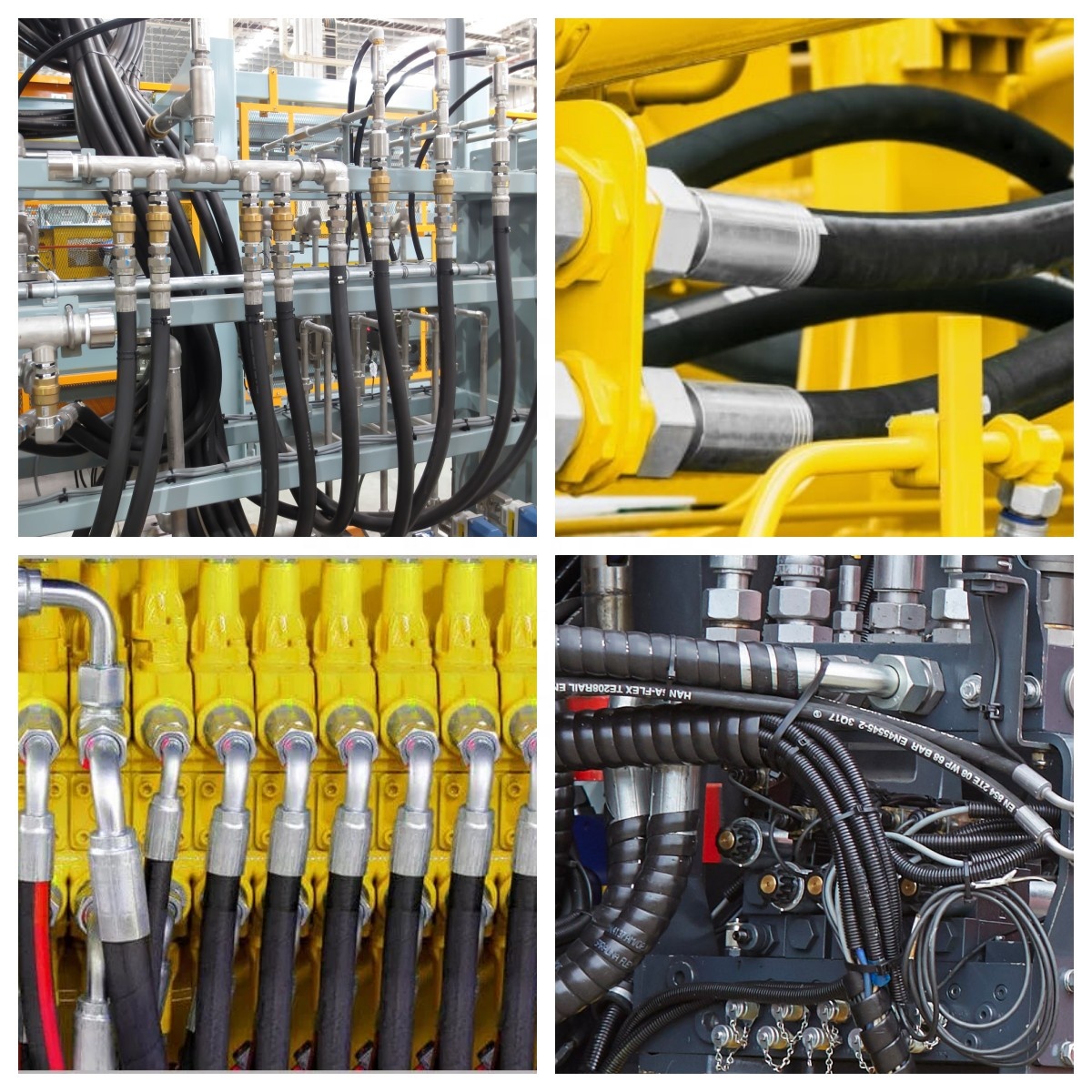

ptfe flexible hose pipe manufacturers

The manufacturing of PTFE flexible hose pipes involves a sophisticated process that demands precision and expertise. Leading manufacturers utilize advanced extrusion technologies to produce high-quality PTFE materials that meet stringent industry standards. The process begins with the extrusion of PTFE resin, followed by the application of reinforcement materials such as stainless steel or braid. This reinforcement offers additional strength and flexibility, essential for handling varying pressures and environments.

After the hose is formed, meticulous testing for quality assurance is conducted. This includes pressure testing, leak testing, and dimensional inspections to ensure that each product meets the required specifications. Manufacturers also put emphasis on customization, allowing the production of hoses tailored to specific lengths, diameters, and configurations to accommodate unique customer requirements.

Choosing the Right Manufacturer

When selecting a PTFE flexible hose pipe manufacturer, several factors should be taken into consideration. First and foremost, it is crucial to verify the manufacturer's reputation and experience in producing high-quality PTFE products. Assessing their certifications and adherence to international standards can also provide insights into their commitment to quality.

Additionally, potential customers should evaluate the range of products offered by the manufacturer. A diverse portfolio can indicate the manufacturer's capability to meet varied industrial needs. Lastly, excellent customer service and support are essential, as they facilitate a smooth purchasing process and ongoing assistance.

Conclusion

PTFE flexible hose pipe manufacturers play a pivotal role in delivering essential components that ensure the efficiency and safety of industrial processes. With applications spanning multiple sectors, the demand for high-quality PTFE hoses continues to grow. As industries evolve and face new challenges, these manufacturers will remain integral in providing innovative and reliable solutions that contribute to operational excellence. Selecting the right manufacturer is not merely a matter of procurement but a strategic decision that impacts an organization’s productivity and success. As such, investing time in researching and choosing the right PTFE flexible hose pipe supplier is of utmost importance for any business relying on these vital components.

-

SAE 100 R3 / EN854 R3 Hydraulic Hose | Medium Pressure & Flexible

NewsAug.11,2025

-

EN856 4SP Hydraulic Hose: High-Pressure & Durable Solutions

NewsAug.11,2025

-

Premium Soft Rubber Tubing: Flexible & Durable Hose Solutions

NewsAug.10,2025

-

Premium Distribution PTFE Hose | Flexible & Durable Solutions

NewsAug.09,2025

-

Premium 38mm Hydraulic Hose Factories | Direct & Reliable

NewsAug.08,2025

-

Premium Wire Braided Hydraulic Hose - Steel Reinforced for Durability

NewsAug.07,2025