335345435

Pro . 17, 2024 16:55 Back to list

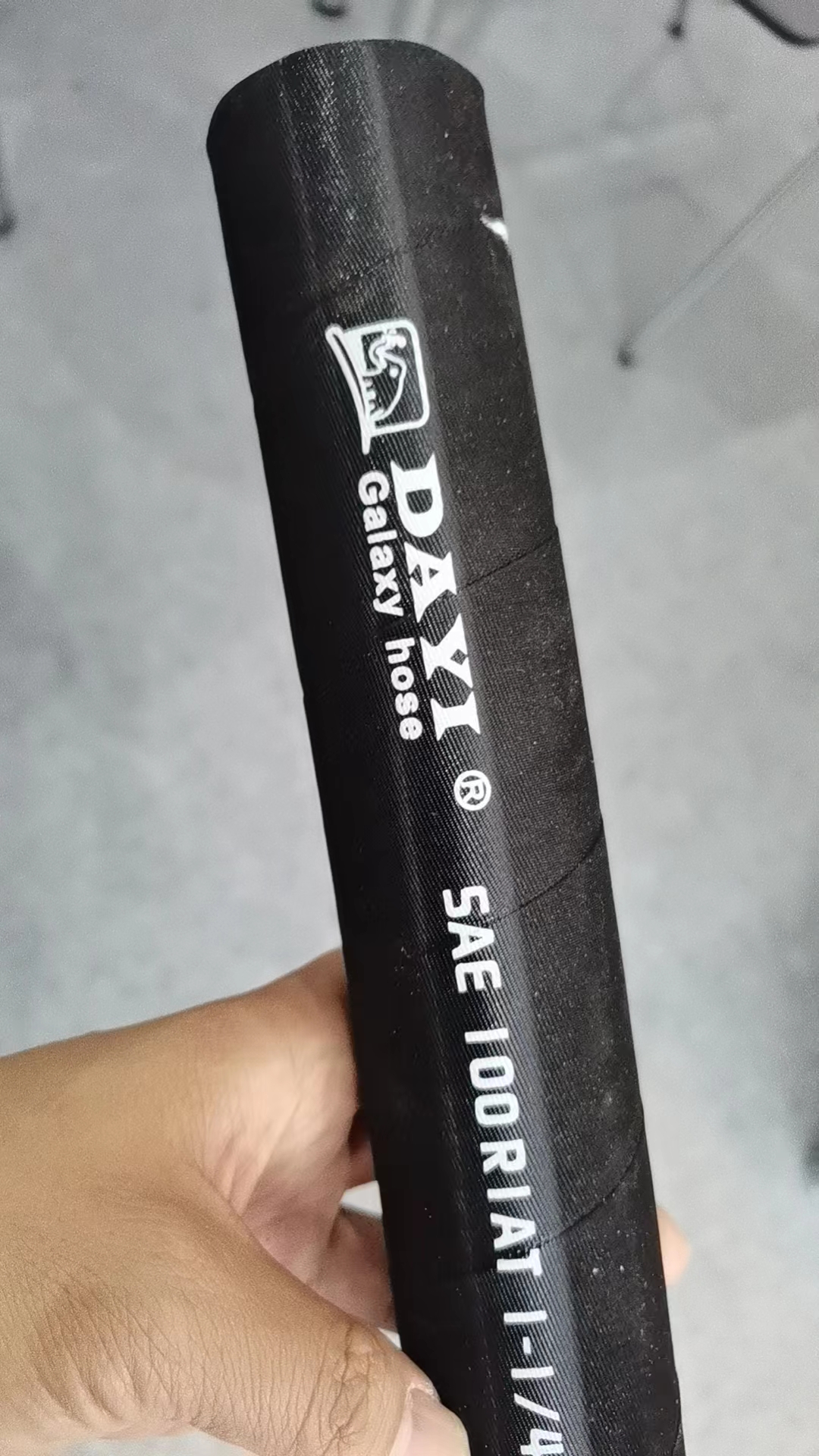

oem steel wire braided hydraulic hose suppliers

Understanding OEM Steel Wire Braided Hydraulic Hose Suppliers

In the world of industrial applications, whether in manufacturing, construction, or automotive sectors, hydraulic systems play a crucial role in ensuring machinery operates smoothly and efficiently. A key component of these systems is the hydraulic hose, and among the various types available, OEM (Original Equipment Manufacturer) steel wire braided hydraulic hoses are particularly noteworthy. This article explores the significance of these hoses, their advantages, and the role of suppliers in the market.

What is Steel Wire Braided Hydraulic Hose?

Steel wire braided hydraulic hoses are designed to withstand high pressures and extreme conditions. These hoses are constructed with multiple layers, featuring a rubber and thermoplastic inner lining that is reinforced with steel wire braiding. The steel braiding provides additional strength and durability, making these hoses suitable for applications where flexibility is vital but where pressure loads and environmental factors can potentially cause failure. They are commonly used in hydraulic machinery for transferring hydraulic fluids, ensuring that the systems are both efficient and safe.

The Importance of OEM Standards

OEM steel wire braided hydraulic hoses are manufactured according to strict standards set by equipment manufacturers. This ensures that the hoses are perfectly compatible with specific machinery and can deliver the performance expected in demanding environments. Utilizing OEM hoses helps in maintaining warranty compliance and assures users of the quality and reliability of the component. Additionally, OEM hoses are typically subjected to rigorous testing procedures, ensuring they can withstand the pressures and conditions they will face in application.

Advantages of Steel Wire Braided Hydraulic Hoses

1. High Pressure Resistance One of the primary advantages of steel wire braided hoses is their ability to handle high pressure. This makes them ideal for heavy-duty equipment and applications where traditional hoses might fail.

3. Flexibility Despite their robust construction, these hoses maintain a certain degree of flexibility, allowing for easier installation and routing in complex machinery without risking kinking.

oem steel wire braided hydraulic hose suppliers

4. Temperature Tolerance They are capable of performing in high and low-temperature environments, making them versatile for various industrial applications.

5. Safety The use of high-quality materials and stringent standards means that OEM steel wire braided hoses come with a greater level of safety assurance against blows and ruptures.

Choosing the Right Supplier

When it comes to sourcing OEM steel wire braided hydraulic hoses, selecting a reliable supplier is paramount. A good supplier should have several key attributes

- Reputation Consider suppliers with positive reviews and testimonials in the industry. A reputable supplier often has a track record of delivering quality products and excellent customer service.

- Quality Assurance The supplier should comply with industry standards and certifications, providing assurance that their hoses meet OEM specifications.

- Diversity of Products A diverse inventory allows customers to find the specific type and specification required for their application.

- Technical Support Suppliers that offer technical assistance can help in selecting the right hose for your specific needs and assist in troubleshooting any issues that may arise.

Conclusion

OEM steel wire braided hydraulic hoses are essential components in various industries, providing the durability and performance needed for hydraulic systems. Understanding their advantages and working closely with reputable suppliers ensures that businesses can maintain efficient operations while upholding safety standards. As hydraulic technology continues to advance, the demand for high-quality hoses like these is expected to grow, making it even more crucial for industries to choose the right products from dependable sources.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025