335345435

Úno . 02, 2025 02:51 Back to list

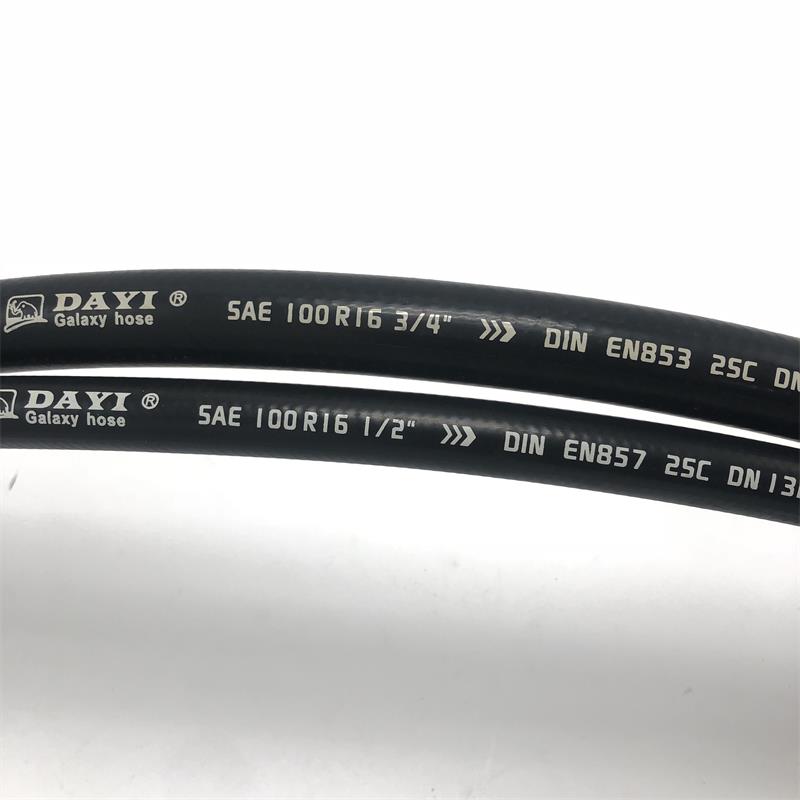

steel wire braided hydraulic hose

OEM high-pressure steel wire braided hydraulic hoses are indispensable components in various heavy machinery and industrial systems. These hoses are not just conduits for hydraulic fluids; they are crucial for ensuring efficiency, safety, and operational performance across many sectors. Having worked closely with these systems over the years, I've realized the pivotal role they play in industrial operations.

Authoritative manufacturers always include thorough documentation outlining the pressure ratings, temperature tolerances, and recommended fluid compatibility for their hoses. This information is invaluable for ensuring that hoses are correctly matched to specific applications, thus avoiding operational mishaps or failures. Moreover, reputable OEMs often provide technical support and after-sales service, critical for maintaining system integrity and promptly addressing any issues that arise during hose operation. Trust in these hydraulic components extends beyond their physical attributes to the reputation and reliability of the OEM. Having reliable partners for these critical components can significantly impact an entity's operational success. Therefore, choosing OEMs known for their stringent quality assurance processes and robust product feedback loops is critical. Companies often seek OEMs with accreditations from industry-respected bodies or compliance with international standards like ISO or SAE, as these endorsements verify that the products can be trusted for high-stakes industrial use. In real-world applications, using trusted OEM high-pressure steel wire braided hydraulic hoses translates into tangible business benefits. These include reduced downtime thanks to fewer hose failures, enhanced safety for operators due to reliable performance under pressure, and lower maintenance costs because of the extended lifespan of high-quality hoses. Operators often share anecdotal evidence of how switching to a reputed OEM product led to significant savings and improvements in operational efficiencies. In essence, selecting the right OEM for high-pressure hydraulic hoses is not merely about purchasing a component; it's about investing in the performance and reliability of an entire hydraulic system. By acknowledging the expertise that OEMs bring to the table, businesses can not only meet but exceed their operational goals, turning their hydraulic systems into a backbone of reliability and efficiency in their respective industries.

Authoritative manufacturers always include thorough documentation outlining the pressure ratings, temperature tolerances, and recommended fluid compatibility for their hoses. This information is invaluable for ensuring that hoses are correctly matched to specific applications, thus avoiding operational mishaps or failures. Moreover, reputable OEMs often provide technical support and after-sales service, critical for maintaining system integrity and promptly addressing any issues that arise during hose operation. Trust in these hydraulic components extends beyond their physical attributes to the reputation and reliability of the OEM. Having reliable partners for these critical components can significantly impact an entity's operational success. Therefore, choosing OEMs known for their stringent quality assurance processes and robust product feedback loops is critical. Companies often seek OEMs with accreditations from industry-respected bodies or compliance with international standards like ISO or SAE, as these endorsements verify that the products can be trusted for high-stakes industrial use. In real-world applications, using trusted OEM high-pressure steel wire braided hydraulic hoses translates into tangible business benefits. These include reduced downtime thanks to fewer hose failures, enhanced safety for operators due to reliable performance under pressure, and lower maintenance costs because of the extended lifespan of high-quality hoses. Operators often share anecdotal evidence of how switching to a reputed OEM product led to significant savings and improvements in operational efficiencies. In essence, selecting the right OEM for high-pressure hydraulic hoses is not merely about purchasing a component; it's about investing in the performance and reliability of an entire hydraulic system. By acknowledging the expertise that OEMs bring to the table, businesses can not only meet but exceed their operational goals, turning their hydraulic systems into a backbone of reliability and efficiency in their respective industries.

Share

Latest news

-

SAE 100 R3 / EN854 R3 Hydraulic Hose | Medium Pressure & Flexible

NewsAug.11,2025

-

EN856 4SP Hydraulic Hose: High-Pressure & Durable Solutions

NewsAug.11,2025

-

Premium Soft Rubber Tubing: Flexible & Durable Hose Solutions

NewsAug.10,2025

-

Premium Distribution PTFE Hose | Flexible & Durable Solutions

NewsAug.09,2025

-

Premium 38mm Hydraulic Hose Factories | Direct & Reliable

NewsAug.08,2025

-

Premium Wire Braided Hydraulic Hose - Steel Reinforced for Durability

NewsAug.07,2025