335345435

Lis . 24, 2024 07:37 Back to list

OEM suppliers for four wire spiral hydraulic hoses with high quality and durability

The Growing Demand for OEM Four Wire Spiral Hydraulic Hose Suppliers

In today’s industrial landscape, the demand for high-performance hydraulic hoses has surged, particularly for OEM (Original Equipment Manufacturer) four wire spiral hydraulic hoses. These hoses are renowned for their ability to handle high pressures and provide superior flexibility and durability, making them essential components in various sectors such as construction, agriculture, manufacturing, and automotive industries.

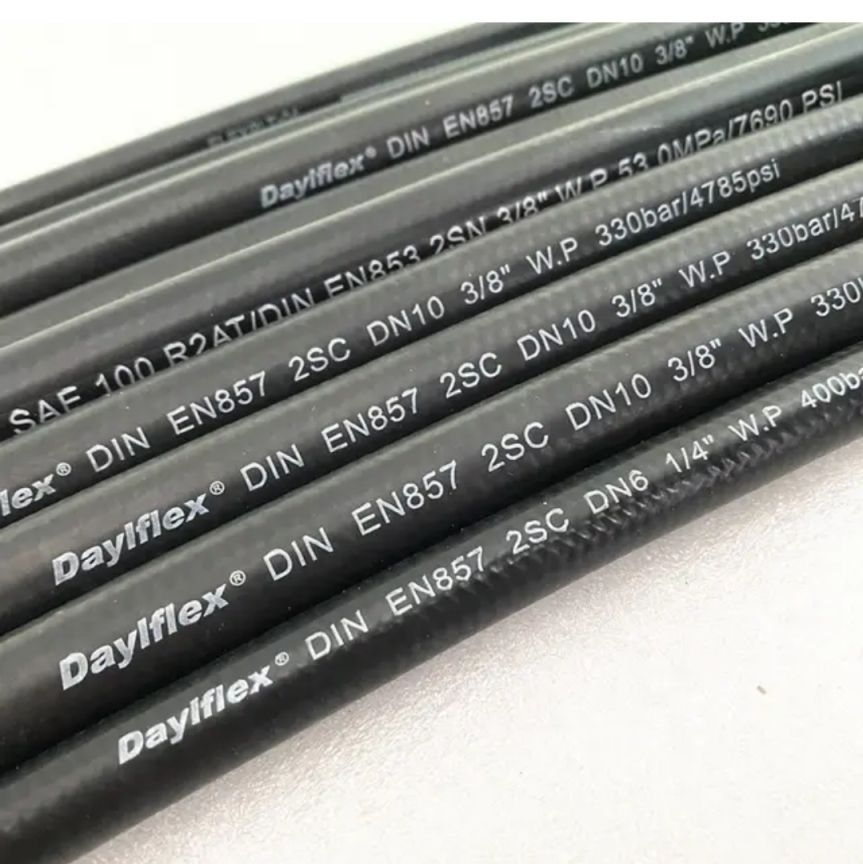

OEM four wire spiral hydraulic hoses are designed to withstand extreme conditions, enabling them to operate effectively in demanding environments. The construction of these hoses features a robust design, typically comprised of an inner tube made from synthetic rubber, reinforcing layers of steel wire, and an outer cover designed to resist abrasion and weathering. The unique four-wire spiral design offers enhanced pressure ratings and flexibility, making these hoses suitable for high-performance applications.

As industrial operations become increasingly complex, the pressure requirements on hydraulic equipment have intensified. Four wire spiral hydraulic hoses can handle pressures exceeding 4000 PSI, which is crucial for industries that rely on hydraulic systems to power machinery. This capability allows manufacturers to improve the overall efficiency and productivity of their operations while ensuring the safety and reliability of their equipment.

Key Suppliers in the Market

With the rising popularity of four wire spiral hydraulic hoses, a number of OEM suppliers have emerged, specializing in manufacturing and supplying these essential components

. These suppliers play a vital role in ensuring that businesses have access to high-quality hoses that meet their specific requirements.When choosing a supplier, it is crucial to consider their experience, product quality, and customer service. Look for suppliers with a proven track record in the industry, who can provide certifications and test data to demonstrate the reliability of their products. Additionally, a good supplier should offer a wide range of sizes, materials, and configurations to cater to diverse application needs.

oem four wire spiral hydraulic hose suppliers

Leading manufacturers often invest in advanced technology and equipment to produce hoses that meet international quality standards. This investment not only enhances the quality of the hoses but also enables the suppliers to innovate and develop new products that can better serve the evolving needs of their customers.

Factors Influencing Supplier Selection

Several factors influence businesses when selecting OEM four wire spiral hydraulic hose suppliers. Firstly, product quality is paramount. High-quality hoses contribute to fewer equipment failures and downtime, directly impacting operational efficiency. Secondly, cost is a significant consideration. While it's important to find a supplier that offers competitive prices, businesses should balance cost with quality to avoid compromising on performance.

Another essential factor is the supplier's ability to provide timely delivery. In industries that rely heavily on hydraulic systems, delays can lead to substantial losses. Therefore, suppliers with a history of reliability and quick response times can provide a distinct advantage.

Conclusion

The demand for OEM four wire spiral hydraulic hoses continues to grow, driven by the need for reliable and high-performance hydraulic solutions. As businesses increasingly rely on hydraulic systems, the importance of selecting the right suppliers becomes evident. By considering factors such as product quality, cost, and delivery reliability, companies can ensure they partner with suppliers that meet their operational needs effectively.

Investing in top-quality OEM four wire spiral hydraulic hoses not only enhances machinery performance but also contributes to a safer working environment. As industries continue to innovate and expand, the role of skilled suppliers in providing essential components cannot be overstated.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025