335345435

Pro . 19, 2024 15:45 Back to list

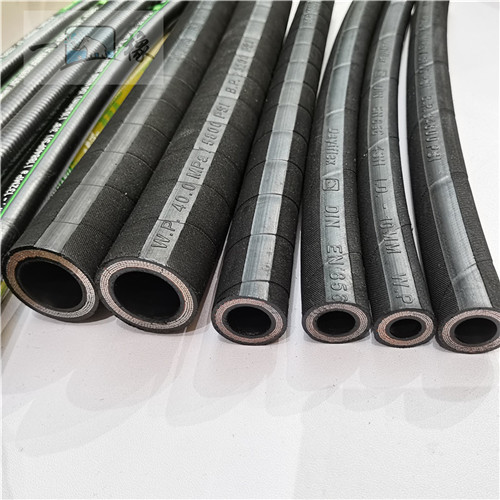

OEM Manufacturers of Fiber Braid Hydraulic Hoses for Reliable Performance and Quality

The Growing Demand for OEM Fiber Braid Hydraulic Hose Manufacturers

In the realm of industrial applications, hydraulic hoses play a pivotal role in the operation of machinery and equipment. Among these, OEM (Original Equipment Manufacturer) fiber braid hydraulic hoses have garnered significant attention due to their enhanced durability, flexibility, and resistance to various environmental factors. As industries evolve and demand for reliable hydraulic systems increases, the market for OEM fiber braid hydraulic hose manufacturers is witnessing substantial growth.

Understanding OEM Fiber Braid Hydraulic Hoses

OEM fiber braid hydraulic hoses are designed to meet the stringent specifications of original equipment manufacturers. These hoses are typically constructed using high-strength fiber braiding, which provides an exceptional level of tensile strength and flexibility. Compared to traditional rubber hoses, fiber braid hoses excel in handling higher pressures and are more resistant to abrasion and wear. Their lightweight nature also contributes to improved maneuverability and ease of installation.

The construction of these hoses often incorporates multiple layers, allowing them to withstand extreme temperature variations and corrosive environments. This multi-layer design ensures that the hoses maintain their integrity over prolonged periods, which is crucial for avoiding expensive downtime in industrial operations.

Key Advantages of Fiber Braid Hydraulic Hoses

1. Enhanced Durability Fiber braid technology significantly enhances the durability of hydraulic hoses. The robust construction offers resistance to cuts, abrasions, and impacts, making them ideal for use in rugged industrial settings.

2. Higher Pressure Ratings OEM fiber braid hoses can handle higher pressures compared to standard hoses, making them suitable for demanding applications where safety and performance are paramount.

3. Temperature Resilience These hoses are often engineered to withstand extreme temperatures, allowing for versatility across various industrial environments.

oem fiber braid hydraulic hose manufacturers

5. Customization Options Many OEM manufacturers offer customized solutions tailored to specific application requirements, ensuring that clients receive products that meet their unique needs.

The Role of Manufacturers in the Market

As the demand for OEM fiber braid hydraulic hoses grows, so does the necessity for reliable manufacturers who can deliver high-quality products. Manufacturers play a crucial role in ensuring that these hoses meet industry standards and regulations. This includes adhering to certifications such as ISO and SAE, which are essential for maintaining quality assurance in the production process.

Many manufacturers employ advanced technologies in their production lines, including automated machinery and strict quality control protocols. This investment in technology not only enhances efficiency but also ensures that each product is consistently reliable and durable.

Furthermore, manufacturers often focus on sustainable practices by utilizing environmentally friendly materials and processes. This not only aligns with global trends toward sustainability but also appeals to customers who prioritize eco-friendly solutions in their operations.

Market Trends and Future Outlook

The market for OEM fiber braid hydraulic hoses is expected to continue its upward trajectory as industries increasingly recognize the advantages of these advanced hoses. Sectors such as construction, agriculture, and automotive are particularly notable for their reliance on hydraulic systems, creating a steady demand for innovative hose solutions.

Additionally, the rise of automated machinery and advanced hydraulic systems in various industries suggests a shift toward more sophisticated hydraulic components. Manufacturers are likely to invest in research and development to create hoses that further enhance performance and meet the evolving needs of their clients.

In conclusion, the growing demand for OEM fiber braid hydraulic hoses reflects a broader trend towards efficiency, durability, and reliability in manufacturing. As industries face mounting pressure to optimize their operations, the role of manufacturers in providing high-quality, tailored solutions will be more critical than ever. The future of OEM fiber braid hydraulic hoses looks promising, with ample opportunities for innovation and growth in this vital segment of the industrial market.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025