335345435

Úno . 03, 2025 05:43 Back to list

DIN-EN 857 1SC Low Temperature -55 ℃ Smooth Cloth Hydraulic hose

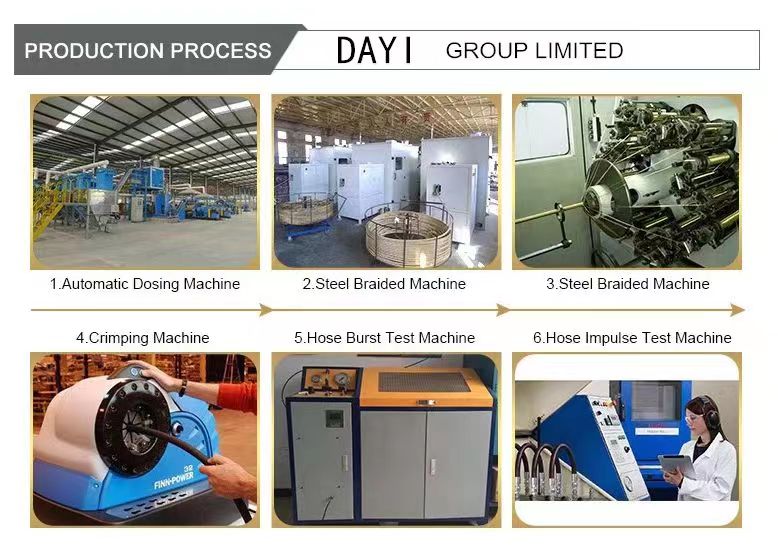

Hydraulic systems power numerous heavy-duty applications, from industrial machinery to automotive systems. Central to these systems is the hydraulic hose, a critical component tasked with transmitting high-pressure fluids efficiently and safely. Among the various types of hydraulic hoses, OEM fiber braid hydraulic hoses have emerged as a leading solution, combining durability with flexible design to meet a range of OEM specifications.

Expert installation and selection are critical for optimizing the performance of OEM fiber braid hydraulic hoses. It is advised to work with experienced professionals who can guide the selection process, ensuring that the right hose is chosen for the specific application considering factors such as operating pressure, temperature, and compatibility with hydraulic fluid types. Furthermore, proper installation by trained technicians is vital to prevent premature wear and operational failures, further enhancing the reliability and efficiency of the hydraulic system. OEM fiber braid hydraulic hoses also excel in adaptability. With the growing demand for more sustainable and efficient equipment, these hoses enable manufacturers to meet and exceed environmental standards. Their inherent flexibility and strength can support the development and integration of more advanced hydraulic technologies that require reliable fluid transfer solutions. For companies seeking to maximize their equipment's performance while minimizing operational complications, OEM fiber braid hydraulic hoses represent a smart investment. Their ability to provide robust performance under high pressure, resist environmental challenges, and customize to specific applications makes them an essential component in modern hydraulic systems. As technology and demands evolve, the adaptability, strength, and reliability of fiber braid hoses will continue to make them a preferred choice for original equipment manufacturers around the world. Collaborating with reputable manufacturers ensures access to the highest quality hoses designed to exceed expectations and deliver ongoing operational excellence.

Expert installation and selection are critical for optimizing the performance of OEM fiber braid hydraulic hoses. It is advised to work with experienced professionals who can guide the selection process, ensuring that the right hose is chosen for the specific application considering factors such as operating pressure, temperature, and compatibility with hydraulic fluid types. Furthermore, proper installation by trained technicians is vital to prevent premature wear and operational failures, further enhancing the reliability and efficiency of the hydraulic system. OEM fiber braid hydraulic hoses also excel in adaptability. With the growing demand for more sustainable and efficient equipment, these hoses enable manufacturers to meet and exceed environmental standards. Their inherent flexibility and strength can support the development and integration of more advanced hydraulic technologies that require reliable fluid transfer solutions. For companies seeking to maximize their equipment's performance while minimizing operational complications, OEM fiber braid hydraulic hoses represent a smart investment. Their ability to provide robust performance under high pressure, resist environmental challenges, and customize to specific applications makes them an essential component in modern hydraulic systems. As technology and demands evolve, the adaptability, strength, and reliability of fiber braid hoses will continue to make them a preferred choice for original equipment manufacturers around the world. Collaborating with reputable manufacturers ensures access to the highest quality hoses designed to exceed expectations and deliver ongoing operational excellence.

Share

Latest news

-

SAE 100 R3 / EN854 R3 Hydraulic Hose | Medium Pressure & Flexible

NewsAug.11,2025

-

EN856 4SP Hydraulic Hose: High-Pressure & Durable Solutions

NewsAug.11,2025

-

Premium Soft Rubber Tubing: Flexible & Durable Hose Solutions

NewsAug.10,2025

-

Premium Distribution PTFE Hose | Flexible & Durable Solutions

NewsAug.09,2025

-

Premium 38mm Hydraulic Hose Factories | Direct & Reliable

NewsAug.08,2025

-

Premium Wire Braided Hydraulic Hose - Steel Reinforced for Durability

NewsAug.07,2025