335345435

Úno . 08, 2025 06:58 Back to list

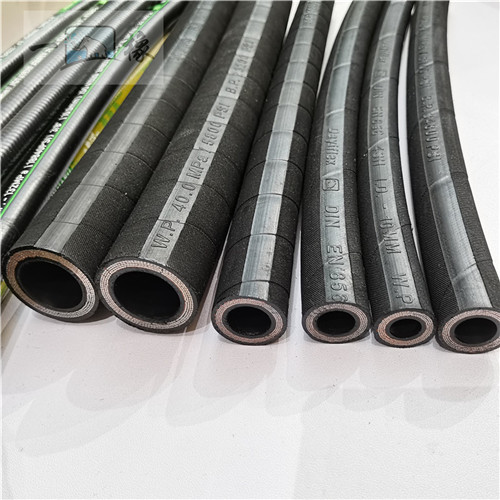

DIN EN 857 2SC Oil Tube Low Temperature -55°c wire braided hose

In the rapidly evolving industrial world, hydraulic hose factories have cemented their importance as essential players in ensuring the seamless operation of various machinery and equipment. But what makes a hydraulic hose factory thrive in such a competitive niche? Delving into the realms of experience, expertise, authoritativeness, and trustworthiness unveils the intricate tapestry that defines top-tier hydraulic hose manufacturers.

The commitment to sustainability is a recent yet impactful trend that further differentiates leading hydraulic hose factories. Innovative recycling methods, energy-efficient manufacturing processes, and the development of eco-friendly materials are becoming increasingly prevalent. This not only appeals to environmentally-conscious clients but also aligns with global efforts to minimize industrial ecological footprints. Furthermore, digital transformation plays a crucial role in the modernization of hydraulic hose factories. With the integration of IoT devices, manufacturers can now provide smart hoses that report real-time data and diagnostics. Such innovations lead to predictive maintenance, reducing downtime and extending the life of the machinery. Factories that embrace these technological advancements clearly demonstrate their forward-thinking approach and commitment to providing state-of-the-art solutions. The reliability of hydraulic hoses is critical. The consequences of hose failure in sectors like construction, mining, and manufacturing can be catastrophic, leading to extensive downtime and financial loss. Therefore, the onus is on these factories to continually meet and exceed client expectations by ensuring that their products operate flawlessly even in the harshest of conditions. In conclusion, the competitiveness of hydraulic hose factories is underpinned by their experience, technical expertise, authoritativeness, and trustworthiness. These elements collectively empower factories to deliver robust products that cater to dynamic industrial needs. As the landscape continues to evolve, those factories that adapt to environmental considerations and technological advancements will likely lead the charge in shaping the future of the hydraulic hose industry.

The commitment to sustainability is a recent yet impactful trend that further differentiates leading hydraulic hose factories. Innovative recycling methods, energy-efficient manufacturing processes, and the development of eco-friendly materials are becoming increasingly prevalent. This not only appeals to environmentally-conscious clients but also aligns with global efforts to minimize industrial ecological footprints. Furthermore, digital transformation plays a crucial role in the modernization of hydraulic hose factories. With the integration of IoT devices, manufacturers can now provide smart hoses that report real-time data and diagnostics. Such innovations lead to predictive maintenance, reducing downtime and extending the life of the machinery. Factories that embrace these technological advancements clearly demonstrate their forward-thinking approach and commitment to providing state-of-the-art solutions. The reliability of hydraulic hoses is critical. The consequences of hose failure in sectors like construction, mining, and manufacturing can be catastrophic, leading to extensive downtime and financial loss. Therefore, the onus is on these factories to continually meet and exceed client expectations by ensuring that their products operate flawlessly even in the harshest of conditions. In conclusion, the competitiveness of hydraulic hose factories is underpinned by their experience, technical expertise, authoritativeness, and trustworthiness. These elements collectively empower factories to deliver robust products that cater to dynamic industrial needs. As the landscape continues to evolve, those factories that adapt to environmental considerations and technological advancements will likely lead the charge in shaping the future of the hydraulic hose industry.

Share

Latest news

-

Parker Teflon Hose Factories: AI-Enhanced Quality Solutions

NewsAug.04,2025

-

High-Performance Distribution PTFE Hose | Long Lifespan

NewsAug.03,2025

-

Premium Hydraulic Hose Wholesale | Bulk Savings & Durability

NewsAug.02,2025

-

Premium Chemical Resistant Distribution PTFE Hose

NewsAug.01,2025

-

Industrial Distribution PTFE Hose - High Purity & Flexibility

NewsJul.31,2025

-

Durable Twin Hydraulic Hose for High-Pressure Systems

NewsJul.31,2025