335345435

Čvn . 28, 2024 03:10 Back to list

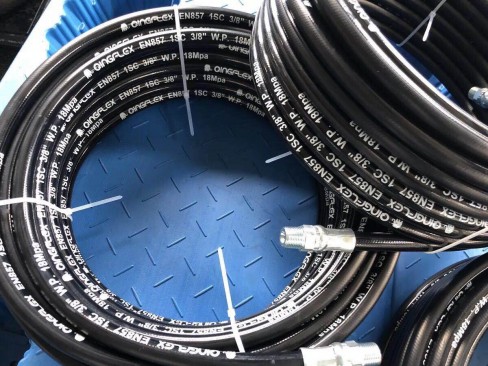

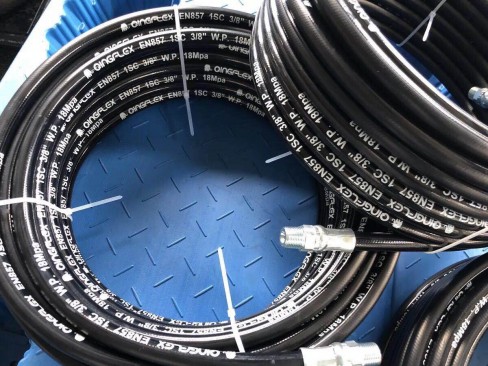

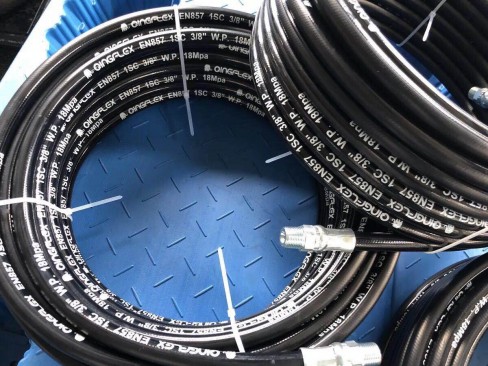

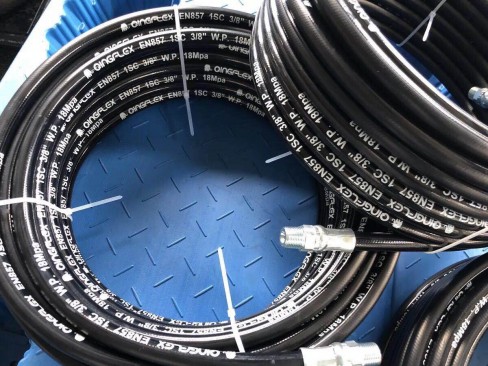

High-pressure Steel Wire Braided Hydraulic Hose for Industrial Applications

Understanding the Strength and Versatility of Steel Wire Braided Hydraulic Hoses

In the world of industrial machinery and fluid power systems, the significance of steel wire braided hydraulic hoses cannot be overstated. These robust and resilient components play a pivotal role in ensuring efficient and safe operation across various industries, from construction to automotive, oil and gas, and manufacturing.

A steel wire braided hydraulic hose, as the name suggests, is a specialized pipe designed for high-pressure hydraulic applications. It is constructed with a core tube made of a highly resistant synthetic rubber, which is then reinforced by one or two layers of high-tensile steel wires braided in a precise pattern. The outer cover, usually made of weather-resistant synthetic rubber, offers additional protection against abrasion, ozone, and chemical exposure.

The primary advantage of steel wire braided hydraulic hoses lies in their exceptional strength and durability. The steel wire reinforcement provides excellent pressure resistance, enabling these hoses to handle extreme working pressures that would rupture other types of hoses. This feature makes them ideal for heavy-duty applications where high pressure and reliability are paramount.

Moreover, the flexibility of these hoses is another key attribute. Despite the steel wire reinforcement, they can bend and flex without losing their integrity, allowing for smooth integration into complex mechanical systems. Their resilience also ensures minimal elongation under pressure, thus maintaining consistent performance Their resilience also ensures minimal elongation under pressure, thus maintaining consistent performance Their resilience also ensures minimal elongation under pressure, thus maintaining consistent performance Their resilience also ensures minimal elongation under pressure, thus maintaining consistent performance

Their resilience also ensures minimal elongation under pressure, thus maintaining consistent performance Their resilience also ensures minimal elongation under pressure, thus maintaining consistent performance steel wire braided hydraulic hose.

The steel wire braided hydraulic hoses are also known for their versatility. They are available in a wide range of sizes, pressure ratings, and temperature tolerances, catering to diverse operational requirements. From low-temperature environments to high-temperature applications, these hoses can withstand a broad spectrum of conditions.

However, it's important to note that proper installation and maintenance are crucial for the longevity and safety of these hoses. Regular inspections for signs of wear, damage, or leaks, and timely replacements are necessary to prevent potential hazards.

In conclusion, steel wire braided hydraulic hoses represent a blend of strength, flexibility, and adaptability, making them indispensable elements in modern hydraulic systems. Their ability to withstand harsh conditions, deliver consistent performance, and ensure safety underscores their value in the industrial landscape. As technology advances, we can expect further enhancements in their design and performance, solidifying their position as a cornerstone of hydraulic engineering.

steel wire braided hydraulic hose.

The steel wire braided hydraulic hoses are also known for their versatility. They are available in a wide range of sizes, pressure ratings, and temperature tolerances, catering to diverse operational requirements. From low-temperature environments to high-temperature applications, these hoses can withstand a broad spectrum of conditions.

However, it's important to note that proper installation and maintenance are crucial for the longevity and safety of these hoses. Regular inspections for signs of wear, damage, or leaks, and timely replacements are necessary to prevent potential hazards.

In conclusion, steel wire braided hydraulic hoses represent a blend of strength, flexibility, and adaptability, making them indispensable elements in modern hydraulic systems. Their ability to withstand harsh conditions, deliver consistent performance, and ensure safety underscores their value in the industrial landscape. As technology advances, we can expect further enhancements in their design and performance, solidifying their position as a cornerstone of hydraulic engineering.

Their resilience also ensures minimal elongation under pressure, thus maintaining consistent performance Their resilience also ensures minimal elongation under pressure, thus maintaining consistent performance

Their resilience also ensures minimal elongation under pressure, thus maintaining consistent performance Their resilience also ensures minimal elongation under pressure, thus maintaining consistent performance steel wire braided hydraulic hose.

The steel wire braided hydraulic hoses are also known for their versatility. They are available in a wide range of sizes, pressure ratings, and temperature tolerances, catering to diverse operational requirements. From low-temperature environments to high-temperature applications, these hoses can withstand a broad spectrum of conditions.

However, it's important to note that proper installation and maintenance are crucial for the longevity and safety of these hoses. Regular inspections for signs of wear, damage, or leaks, and timely replacements are necessary to prevent potential hazards.

In conclusion, steel wire braided hydraulic hoses represent a blend of strength, flexibility, and adaptability, making them indispensable elements in modern hydraulic systems. Their ability to withstand harsh conditions, deliver consistent performance, and ensure safety underscores their value in the industrial landscape. As technology advances, we can expect further enhancements in their design and performance, solidifying their position as a cornerstone of hydraulic engineering.

steel wire braided hydraulic hose.

The steel wire braided hydraulic hoses are also known for their versatility. They are available in a wide range of sizes, pressure ratings, and temperature tolerances, catering to diverse operational requirements. From low-temperature environments to high-temperature applications, these hoses can withstand a broad spectrum of conditions.

However, it's important to note that proper installation and maintenance are crucial for the longevity and safety of these hoses. Regular inspections for signs of wear, damage, or leaks, and timely replacements are necessary to prevent potential hazards.

In conclusion, steel wire braided hydraulic hoses represent a blend of strength, flexibility, and adaptability, making them indispensable elements in modern hydraulic systems. Their ability to withstand harsh conditions, deliver consistent performance, and ensure safety underscores their value in the industrial landscape. As technology advances, we can expect further enhancements in their design and performance, solidifying their position as a cornerstone of hydraulic engineering. Share

Latest news

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025