335345435

Říj . 08, 2024 18:17 Back to list

cng hose factory

CNG Hose Factory The Backbone of Clean Energy Transportation

In an era where sustainable energy solutions are paramount, the role of compressed natural gas (CNG) systems cannot be overstated. As the world transitions from more harmful fossil fuels to cleaner alternatives, CNG emerges as a strong contender in the race for environmental sustainability. At the heart of this transformative journey lies the CNG hose factory, a pivotal contributor in the production of high-quality hoses that ensure the safe and efficient transportation of CNG.

The Importance of CNG Hoses

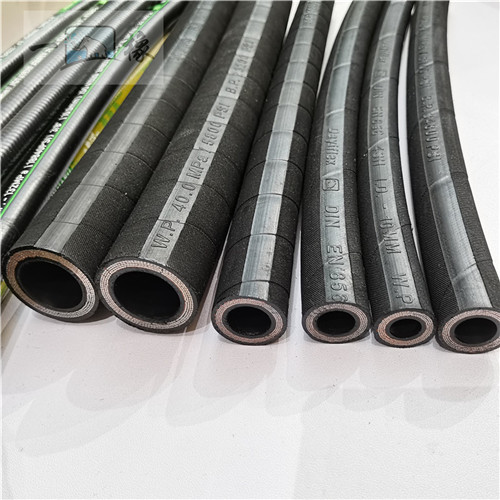

CNG hoses are specialized tubes designed to convey compressed natural gas from one point to another, typically from storage tanks to vehicles or other machinery. These hoses must adhere to stringent safety standards to prevent leaks and ensure that gas is delivered in a reliable manner. The properties of CNG — its high pressure and flammable nature — necessitate the use of hoses made from durable, heat-resistant materials that can withstand both the physical and chemical challenges posed by this gas.

The design and engineering of CNG hoses involve cutting-edge technology and materials. The hoses need to be flexible yet robust, with the ability to endure high pressures while remaining impervious to damage from external factors. This makes the manufacturing processes employed in a CNG hose factory critical to the overall effectiveness and safety of CNG transportation.

Manufacturing Process

The manufacturing process in a CNG hose factory involves several key stages. First, high-quality materials such as rubber, thermoplastics, and reinforcing fibers are selected for their durability and resistance to degradation. The first step is mixing the raw materials, which is crucial for ensuring that the hoses will meet the necessary strength and flexibility requirements.

Once the material is prepared, it is extruded into desired shapes and sizes. This stage of the process requires precision machinery to ensure uniformity and consistency in the diameter and thickness of the hoses. After extrusion, each hose undergoes rigorous testing to check for leaks, pressure loss, and mechanical strength. Testing is a non-negotiable phase in the production of CNG hoses, as even a minute flaw could lead to catastrophic results.

cng hose factory

The quality of the end product is a reflection of the technology and expertise available at the factory. Advanced quality control methods ensure that each hose not only meets but exceeds regulatory standards. The factory's commitment to safety and quality is paramount, particularly given the potential hazards associated with natural gas.

Innovations in CNG Hose Manufacturing

In recent years, the industry has seen significant innovations in CNG hose technology. Improvements in materials science have led to the development of hoses that are not only lighter and more flexible but also more resistant to weathering, abrasion, and chemical exposure. These innovations contribute to longer service life and lower maintenance costs, making CNG systems more appealing for commercial and personal use.

Moreover, the integration of smart technologies into hose manufacturing is on the rise. Sensors can now be embedded in hoses to monitor pressure levels and detect potential leaks in real-time, providing critical data that can prevent accidents and facilitate timely maintenance. This level of technology creates a safer environment not only for operators but also for the surrounding community.

Conclusion

CNG hose factories are essential to the infrastructure supporting compressed natural gas utilization. By producing hoses that meet strict safety standards and technological advancements, these factories play a vital role in promoting cleaner energy solutions. As demand for CNG continues to grow, the importance of high-quality, reliable hoses will only increase. Investment in CNG technology and manufacturing processes paves the way not only for safer transportation of natural gas but also for a more sustainable future.

In summary, the CNG hose factory epitomizes a critical intersection of innovation, safety, and sustainability in the energy sector, helping to drive the world towards a cleaner tomorrow.

-

High-Precision Hydraulic Hose Crimping Machine for Fast, Reliable Fittings

NewsJul.24,2025

-

High-Quality Distribution PTFE Hose for Industrial Flexibility

NewsJul.23,2025

-

Durable Pressure Washer Rubber Hose for Hot Water & High Flexibility

NewsJul.22,2025

-

Twin Hydraulic Hose for Efficient Fluid Transfer | Durable & Flexible

NewsJul.22,2025

-

Twin Hydraulic Hose | High Pressure & Durable

NewsJul.21,2025

-

Discount Hydraulic Hose Factories | Top Quality & Discounts

NewsJul.20,2025