335345435

Pro . 14, 2024 03:50 Back to list

China's Role in Hydraulic Hose Manufacturing Industry and Its Global Impact

The Role of China in Hydraulic Hose Production A Comprehensive Analysis

In recent years, China has established itself as a leading manufacturer of hydraulic hoses, playing an essential role in various industries ranging from construction to agriculture and transportation. Hydraulic hoses are critical components in hydraulic systems, designed to convey fluid under pressure within hydraulic machinery. This article will delve into the significance of China’s hydraulic hose factories, the manufacturing processes involved, and the implications for the global market.

China's Dominance in Hydraulic Hose Manufacturing

China's hydraulic hose production capacity is unparalleled, accounting for a significant percentage of the world’s total output. The country boasts numerous factories equipped with advanced technology and high-level production facilities. This industrial expansion is fueled by a combination of factors, including a vast labor force, substantial investments in modern machinery, and favorable government policies that promote manufacturing and exportation.

The demand for hydraulic hoses continues to rise globally, driven by increased construction activities, industrial automation, and the expansion of transportation infrastructure. Consequently, China's hydraulic hose factories are crucial in satisfying this demand, ensuring the global supply chain remains uninterrupted.

Manufacturing Processes in Hydraulic Hose Production

The manufacturing of hydraulic hoses involves several key stages, each critical to ensuring the final product's performance and reliability. It begins with the selection of raw materials, typically rubber and thermoplastics, which provide flexibility and resistance to abrasion and pressure. The choice of materials directly influences the hose's durability and overall efficiency in hydraulic applications.

Once the materials are selected, the actual fabrication process begins. This involves extruding the rubber to form the hose, followed by the insertion of reinforcing layers, typically made from steel wire or synthetic fibers. These reinforcements are essential for enhancing the hose’s strength, allowing it to withstand high pressure and external environmental factors.

After the hose is constructed, it undergoes rigorous testing to ensure it meets quality standards. This includes pressure testing, bend testing, and aging tests to assess the hose's performance over time. Quality control is a critical component within hydraulic hose factories, as the failure of these components can lead to catastrophic results in hydraulic systems.

china 1/4 in hydraulic hose factories

Impact on the Global Market

China’s robust production capabilities have significant implications for the global hydraulic hose market. The competitive pricing offered by Chinese manufacturers enables companies worldwide to procure high-quality hoses at lower costs. This affordability facilitates the widespread adoption of hydraulic systems in various sectors, thereby accelerating industrial growth, particularly in developing nations.

Furthermore, the international shipping and logistics within China also play a critical role. The country’s efficient supply chain systems, which include advanced transportation networks and ports, ensure timely delivery of products to global markets. Consequently, hydraulic hose suppliers can maintain inventory levels that meet their operational needs without significant delays, enhancing overall productivity.

Future Trends and Sustainability

As global demand for hydraulic hoses continues to grow, it also brings to light the need for sustainable manufacturing practices. Chinese manufacturers are increasingly focusing on reducing their environmental impact by implementing cleaner production techniques and utilizing recycled materials. There is also a growing emphasis on innovation, with companies investing in research and development to create hoses that are not only more efficient but also environmentally friendly.

As we look to the future, several trends are likely to shape the hydraulic hose manufacturing landscape in China. The shift toward automation and smart manufacturing practices is expected to enhance efficiency and consistency in production. Moreover, increased collaboration with international partners will likely lead to knowledge exchange that drives innovation and improves product quality.

Conclusion

In conclusion, China's hydraulic hose factories are integral to the global manufacturing landscape, offering reliability, affordability, and a vast supply of products. As industries worldwide continue to evolve and require advanced hydraulic solutions, China is poised to remain a key player in this market. Through ongoing investment in technology and a commitment to sustainability, Chinese manufacturers will not only meet current demands but will also shape the future of hydraulic hose production in an increasingly interconnected world.

-

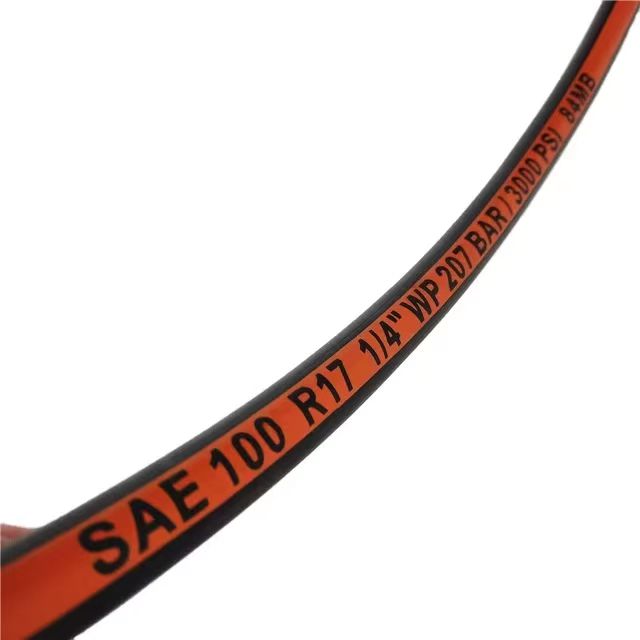

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025