335345435

Pro . 20, 2024 07:37 Back to list

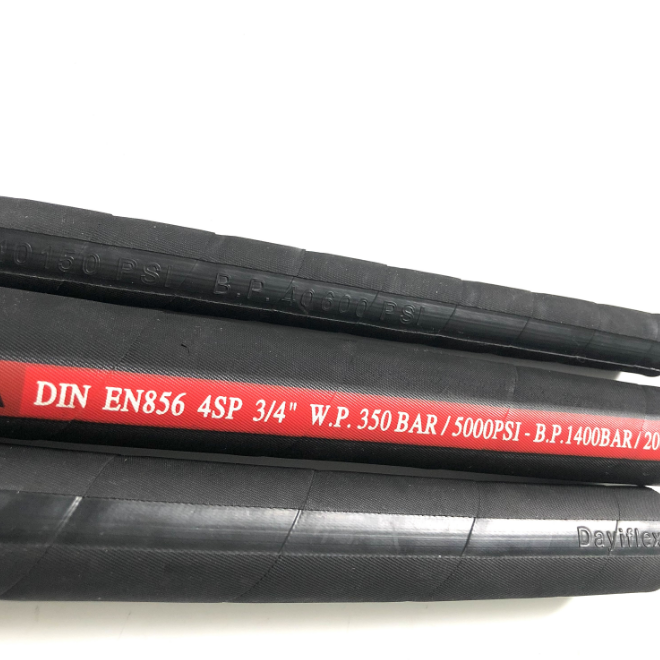

bulk hydraulic hose fittings

Understanding Bulk Hydraulic Hose Fittings

When it comes to hydraulic systems, the importance of a reliable and efficient connection cannot be overstated. One of the critical components ensuring this connection is the bulk hydraulic hose fitting. These fittings play a vital role in the performance and longevity of hydraulic systems across various industries, including construction, automotive, and manufacturing. This article provides an overview of bulk hydraulic hose fittings, their types, applications, and considerations for selection.

What Are Bulk Hydraulic Hose Fittings?

Bulk hydraulic hose fittings are essential components used to connect hoses, tubes, and pipes in hydraulic systems. They facilitate the transfer of hydraulic fluids while accommodating the dynamic nature of fluid movement under pressure. These fittings are often manufactured from durable materials such as steel, stainless steel, and brass, enabling them to withstand high pressure and resist corrosion.

The term bulk typically refers to fittings that are not permanently attached to a hose and can be purchased in larger quantities for assembly at the user's location. This flexibility allows for tailored hydraulic solutions suited to specific applications or system designs.

Types of Bulk Hydraulic Hose Fittings

Bulk hydraulic hose fittings come in a variety of styles and configurations. Here are some of the most common types

1. JIC Fittings (Joint Industry Council) Known for their 37-degree flare angle, JIC fittings are widely used in the hydraulic industry. They provide a tight seal and are interchangeable with other 37-degree flared fittings.

2. NPT Fittings (National Pipe Thread) These tapered fittings are self-sealing and are used primarily for joining pipes. NPT fittings come in various material options and are popular due to their capacity to handle high pressures.

3. BSP Fittings (British Standard Pipe) These fittings are prevalent in the UK and other countries that follow the British plumbing standard. They can come in both parallel and tapered forms, and are known for their compatibility across various systems.

4. Barb Fittings These fittings are often used with flexible hoses and feature a tapered design that ensures a firm grip. They are easy to install and appropriate for low-pressure applications.

5. Camlock Fittings These fittings are quick-connect/disconnect types used in applications requiring frequent assembly and disassembly. They are versatile, allowing for a range of materials and sizes.

Applications of Bulk Hydraulic Hose Fittings

bulk hydraulic hose fittings

Bulk hydraulic hose fittings are utilized in various sectors, including

- Construction Equipment Equipment like excavators, bulldozers, and cranes relies heavily on hydraulic systems for operation. Bulk hydraulic hose fittings enhance these systems' reliability and efficiency. - Manufacturing Hydraulic machines in manufacturing plants, such as presses and injection molding machines, utilize bulk fittings for fluid transfer and operational accuracy. - Automotive In automotive applications, hydraulic systems control everything from power steering to braking, making reliable fittings essential for safety and performance.

- Agriculture Agricultural machinery operates on hydraulics for various functions, including planting, harvesting, and equipment operation. Robust fittings ensure seamless operation even in tough environments.

Considerations for Selecting Bulk Hydraulic Hose Fittings

When choosing bulk hydraulic hose fittings, several factors should be considered to ensure optimal performance

- Material Compatibility Ensure that the fitting material is compatible with the hydraulic fluid being used, as different fluids can cause various materials to degrade over time.

- Pressure Rating Select fittings that can withstand the maximum working pressure of your system. Underrating fittings can lead to catastrophic failures.

- Size and Compatibility Ensure that the fittings match the hose diameter and thread specifications of the hydraulic system to avoid leaks and ensure a secure connection.

- Environmental Factors Consider where the fittings will be used. Exposure to harsh conditions, such as chemicals or extreme temperatures, may require specialized materials or coatings.

- Ease of Assembly Some fittings offer easier assembly options than others. Depending on your specific application, ease of installation might be a priority.

Conclusion

Bulk hydraulic hose fittings are indispensable components of hydraulic systems, ensuring safe and efficient fluid transfer. With various types and applications available, selecting the right fitting requires careful consideration of compatibility, pressure ratings, and environmental factors. By understanding the significance and function of these fittings, users can optimize their hydraulic systems for reliability and performance.

-

Global Distribution PTFE Hose | Flexible & Steel-Braided

NewsAug.06,2025

-

Parker Teflon Hose Factories: AI-Enhanced Quality Solutions

NewsAug.04,2025

-

High-Performance Distribution PTFE Hose | Long Lifespan

NewsAug.03,2025

-

Premium Hydraulic Hose Wholesale | Bulk Savings & Durability

NewsAug.02,2025

-

Premium Chemical Resistant Distribution PTFE Hose

NewsAug.01,2025

-

Industrial Distribution PTFE Hose - High Purity & Flexibility

NewsJul.31,2025