335345435

Pro . 09, 2024 17:31 Back to list

Top Manufacturers of Braided LPG Gas Hoses for Safe and Efficient Use

The Importance of Quality in Braided LPG Gas Hose Manufacturing

In the world of industrial and domestic applications, the safety and efficiency of gas systems are paramount. This is particularly true in the use of Liquefied Petroleum Gas (LPG), which, while an efficient fuel source, requires reliable and high-quality infrastructure to ensure safe handling. Central to this infrastructure is a vital component the braided LPG gas hose. This article explores the significance of quality in the manufacturing process of braided LPG gas hoses and highlights key manufacturers in the field.

Understanding Braided LPG Gas Hoses

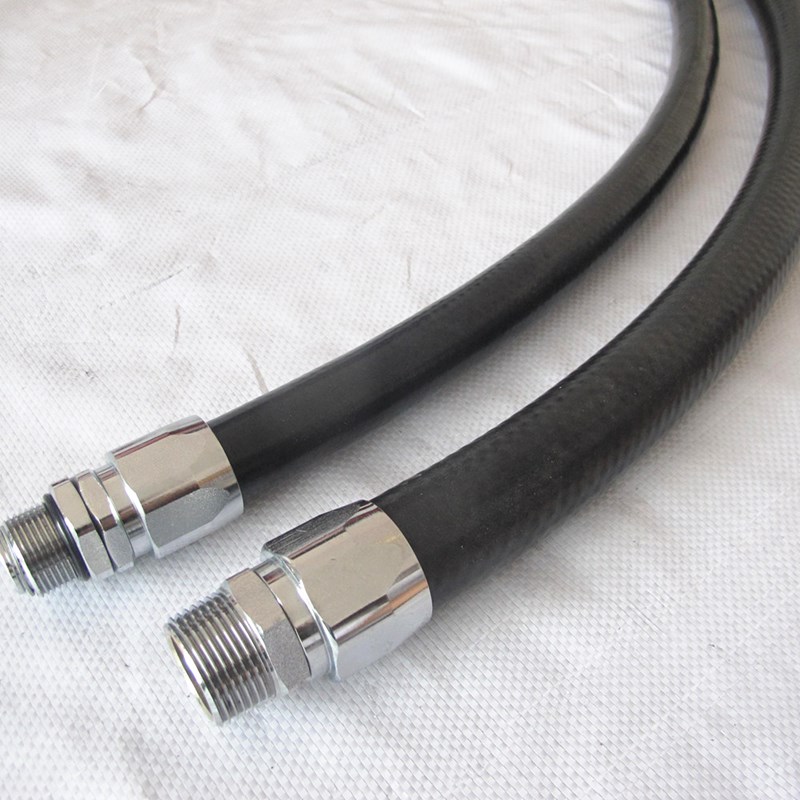

Braided LPG gas hoses are specially designed to transport gas safely under high pressure. They are typically made from a combination of rubber and reinforced materials such as stainless steel or polyester fibers which provide durability and prevent leaks. The braided design enhances flexibility, making it easier to install in various settings, whether it be in residential kitchens or industrial applications.

The importance of selecting a quality manufacturer cannot be overstated. Poorly manufactured hoses can lead to devastating consequences, including gas leaks, fire hazards, and even explosions. Therefore, understanding the manufacturing processes and selecting reputable manufacturers is crucial for both safety and performance.

Key Features of Quality Braided LPG Gas Hoses

1. Material Composition High-quality braided LPG gas hoses are made from premium materials that can withstand extreme temperatures and pressures. The outer layer often includes abrasion-resistant compounds to prevent wear and tear, while the inner layer must resist the corrosive effects of LPG.

2. Reinforcement The braided structure not only provides flexibility but also adds strength. This reinforcement helps prevent bursting under pressure, ensuring the safety of users in case of unexpected situations.

braided lpg gas hose manufacturers

3. Regulatory Compliance Quality manufacturers adhere to strict industry standards and regulations. They obtain certifications from relevant authorities which assure customers of the hoses' performance, reliability, and safety.

4. Testing and Quality Control Leading manufacturers conduct rigorous testing of their products. This includes pressure tests, flexibility tests, and inspections for leaks. Such quality control measures ensure that the hoses meet both customer expectations and safety regulations.

Prominent Manufacturers in the Field

Several manufacturers have established a strong reputation for producing high-quality braided LPG gas hoses. Companies such as Goodyear, Continental, and Parker Hannifin are renowned for their commitment to safety and innovation. These companies invest in advanced technology and research to continuously improve their products, ensuring they meet the evolving needs of consumers and industries alike.

Additionally, regional manufacturers have emerged in various parts of the world, contributing to local economies while also prioritizing quality and safety in their products. It's crucial for consumers to research and choose manufacturers with a proven track record of reliability and customer satisfaction.

Conclusion

In conclusion, the importance of quality in braided LPG gas hose manufacturing cannot be overstated. Safety, reliability, and efficiency hinge on the choice of hoses used in LPG systems. Whether it's for domestic use or industrial applications, selecting a reputable manufacturer that adheres to industry standards and emphasizes quality control is essential. As the demand for LPG continues to grow, the role of manufacturers in providing safe and effective solutions remains critical. By prioritizing quality, manufacturers can help prevent accidents and ensure that the benefits of LPG are enjoyed safely and efficiently.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025