335345435

نوفمبر . 10, 2024 00:03 Back to list

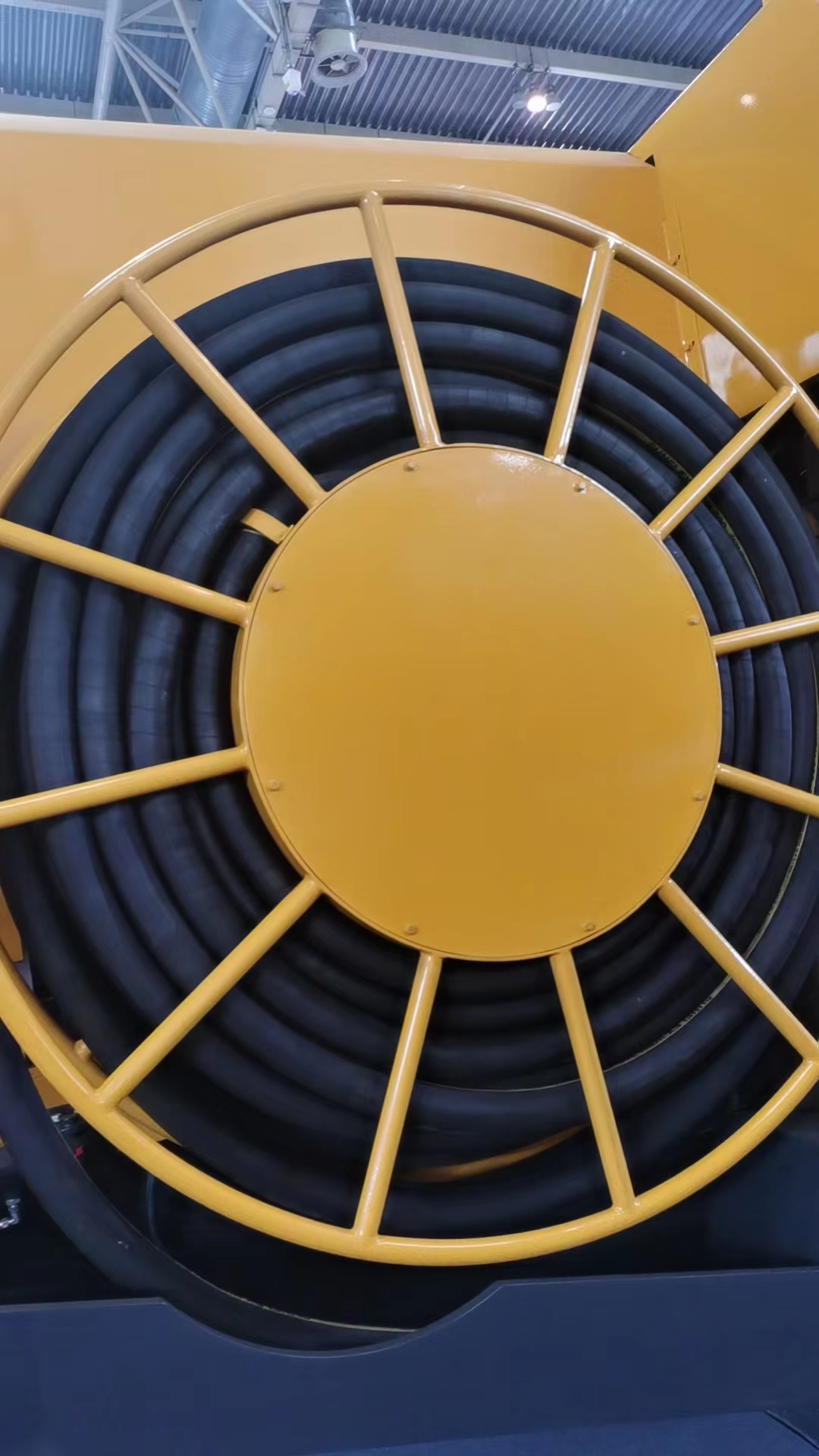

OEM Rubber Hose for Water Suction and Discharge from Leading Factories

OEM Water Suction and Discharge Rubber Hose An Overview of Factories and Manufacturing Processes

In today's industrial landscape, the demand for efficient and reliable water handling solutions has led to the proliferation of OEM (Original Equipment Manufacturer) water suction and discharge rubber hoses. These hoses play a critical role in various applications such as construction, mining, agriculture, and municipal water services. Understanding the manufacturing processes and the factories involved in producing these essential tools can provide valuable insights into their effectiveness and longevity.

What are Water Suction and Discharge Hoses?

Water suction and discharge hoses are specifically designed for the transportation of water, whether it be transferring it from a source to a storage tank or removing it from a site where it may cause flooding. These hoses are typically made from high-quality rubber or PVC, designed to withstand a range of pressures and environmental conditions. Their flexibility and durability make them suitable for both suction and discharge applications where reliable performance is crucial.

The Role of OEM Factories

OEM factories specializing in the production of water suction and discharge hoses are equipped with advanced technologies and skilled professionals who understand the intricacies of hose construction. These factories typically follow a set of stringent quality control measures to ensure that the products meet industry standards. The focus on OEM manufacturing allows for customization based on specific client needs, which can vary significantly across different sectors.

Manufacturing Processes

1. Material Selection The first step in manufacturing hoses is the selection of appropriate materials. Various rubber compounds can be used, each offering different characteristics such as flexibility, temperature resistance, and durability. For instance, synthetic rubber like EPDM (ethylene propylene diene monomer) is often chosen for its excellent weather resistance, while other materials may be selected based on cost-effectiveness or specific application requirements.

oem water suction and discharge rubber hose factories

2. Extrusion The rubber is usually heated and extruded through a die to form the desired hose shape. This process ensures that the hose has consistent wall thickness and size, which is crucial for maintaining pressure during operation. The extrusion process can be adjusted to create hoses of varying diameters and lengths according to specifications.

3. Reinforcement Many water hoses are reinforced with textile or steel wires to improve their pressure capacity and durability. This reinforcement helps prevent hose collapse during suction and ensures that the hose can withstand external stresses during discharge.

4. Curing After extrusion and reinforcement, the hoses undergo a curing process, where they are heated in a mold. This step solidifies the rubber and helps it achieve the necessary strength and flexibility. The curing process is crucial as it affects the final properties of the hose, such as its elasticity and resistance to wear.

5. Quality Control Once the hoses are manufactured, they undergo rigorous quality control testing. This includes checking for proper pressure ratings, flexibility, and resistance to environmental factors. Factories employ various testing methods, such as burst testing, to ensure that the hoses meet industry standards.

6. Customization and Branding OEM factories also offer customization options allowing clients to specify lengths, colors, and branding. Custom solutions can be critical for businesses that require hoses tailored to unique operational needs or branding considerations.

Conclusion

As industries continue to evolve, the need for high-quality, reliable water suction and discharge hoses becomes increasingly significant. OEM factories that specialize in their manufacturing play an essential role in meeting this demand. Utilizing advanced manufacturing processes, these facilities produce hoses that are not only functional but also optimized for various applications.

Through dedicated research and development, coupled with stringent quality control, OEM water suction and discharge rubber hose factories ensure that their products can handle the challenges posed by different environments and tasks. By understanding the intricacies of these manufacturing processes, businesses can make informed decisions when procuring hoses that will serve their operational needs effectively and efficiently.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025