335345435

نوفمبر . 10, 2024 06:49 Back to list

Top Hydraulic Hose Manufacturers for OEM Solutions and Quality Assurance

The Importance of OEM SEL Hydraulic Hose Manufacturers

In today's industrial landscape, hydraulic systems play a pivotal role in various applications, ranging from automotive to heavy machinery and industrial equipment. At the heart of these systems are hydraulic hoses, responsible for transferring fluids under high pressure. While there are many suppliers in the market, Original Equipment Manufacturer (OEM) SEL hydraulic hose manufacturers stand out as key players in ensuring the performance and reliability of hydraulic systems. This article explores the significance of these manufacturers, emphasizing the importance of quality, compatibility, and innovation in hydraulic hose production.

Understanding OEM and SEL Designations

OEM refers to companies that produce parts and equipment that may be marketed or sold by another manufacturer. In the case of hydraulic hoses, OEM manufacturers supply components that are specifically designed to match the specifications of the original machinery they are intended for. SEL, or Special Equipment Manufacturer, indicates a level of specialization, often highlighting manufacturers that create hoses tailored to specific applications or industries. Together, OEM and SEL designations ensure that products meet stringent requirements and performance standards.

The Role of Quality in Hydraulic Hose Manufacturing

One of the primary advantages of sourcing hydraulic hoses from OEM SEL manufacturers is the emphasis on quality. These manufacturers utilize high-quality raw materials and advanced manufacturing processes to produce hoses that can withstand extreme pressures and harsh environmental conditions. The durability and reliability of hydraulic hoses are crucial, as even minor failures can lead to significant downtime and costly repairs.

For instance, OEM SEL hydraulic hoses are typically subjected to rigorous testing to ensure they can handle the required pressure ratings and temperature ranges. This testing includes burst pressure tests, impulse tests, and abrasion resistance assessments. Manufacturers often adhere to industry standards such as SAE, ISO, and EN certifications, which provide assurance of quality to end-users.

Compatibility with Equipment

Another significant benefit of OEM SEL hydraulic hose manufacturers is their focus on compatibility. Unlike generic hoses, which may not fit perfectly or perform adequately in specific applications, OEM hoses are designed to match the exact specifications and performance characteristics of the equipment they are intended for. This compatibility helps avoid leaks, reduce wear and tear, and ensure optimal performance of the hydraulic systems.

oem sel hydraulic hose manufacturers

For example, in the automotive industry, using the correct OEM hydraulic hoses can significantly enhance the efficiency and safety of vehicles. Similarly, in agricultural machinery, utilizing the right hoses ensures that hydraulic systems operate smoothly, contributing to increased productivity on farms.

Innovation and Customization

As industries evolve, so do the requirements for hydraulic hoses. OEM SEL manufacturers are often at the forefront of innovation, developing new materials and designs to meet emerging needs. They frequently invest in research and development to enhance the performance and longevity of their products. This innovation is crucial in sectors like construction, where hydraulic systems face demanding conditions.

Customization is another area where OEM SEL hydraulic hose manufacturers excel. They understand that different applications may require unique specifications, whether it’s a specific length, diameter, reinforcement type, or special coatings. This ability to customize hoses ensures that clients receive products that perfectly suit their operational requirements.

The Economic Advantage

While it might be tempting to choose generic hydraulic hoses due to their lower initial costs, the long-term economic benefits of opting for OEM SEL hydraulic hoses often outweigh the savings. High-quality hoses reduce the likelihood of failures and the need for frequent replacements, translating to lower operational costs and minimized downtime.

Furthermore, by investing in reliable hydraulic hoses, businesses can enhance their equipment's efficiency and lifespan, ultimately leading to increased profitability.

Conclusion

In conclusion, OEM SEL hydraulic hose manufacturers play a crucial role in the maintenance and functionality of hydraulic systems across various industries. Their commitment to quality, compatibility, innovation, and customization ensures that businesses can rely on their products for smooth and efficient operations. While the initial investment may be higher than that of generic alternatives, the long-term benefits, including reduced downtime and increased reliability, make OEM SEL hydraulic hoses the smart choice for any organization that depends on hydraulic systems. As industries continue to evolve, partnering with reputable manufacturers will be essential to stay ahead in a competitive marketplace.

-

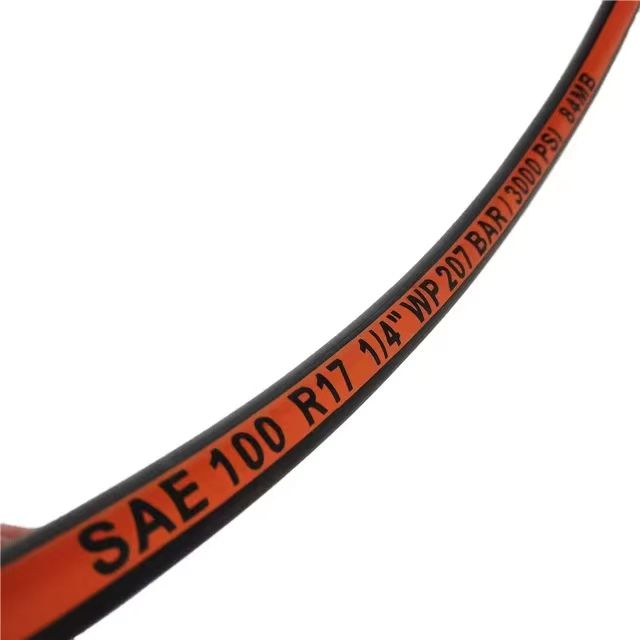

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025