335345435

نوفمبر . 17, 2024 11:51 Back to list

hydraulic hose components

Understanding Hydraulic Hose Components An Essential Guide

Hydraulic systems play a crucial role in various industries, powering machinery, vehicles, and equipment. The efficiency and functionality of these systems heavily rely on hydraulic hoses and their components. In this article, we will explore the essential components of hydraulic hoses, their functions, and their significance in ensuring optimal operation and safety in hydraulic systems.

1. Hydraulic Hoses An Overview

Hydraulic hoses are flexible tubes designed to transport fluid under high pressure within hydraulic systems. They are critical components that connect various parts of hydraulic machinery, allowing for the transfer of hydraulic fluid. These hoses are typically made from synthetic rubber or thermoplastic materials, reinforced with layers of fabric or steel wire to withstand the immense pressures they encounter during operation.

2. Components of Hydraulic Hoses

The effectiveness of hydraulic hoses depends on several key components

a. Hose Tube

The inner layer, or hose tube, is responsible for carrying the hydraulic fluid. It is crucial that this layer is resistant to the specific type of fluid being used, as well as to temperature and pressure variations. The choice of materials for the hose tube can impact the hose's durability and longevity.

To prevent bursting under high pressure, hydraulic hoses are reinforced with layers of braided steel wire or textile fibers. This reinforcement adds strength and flexibility, allowing the hose to withstand the demanding environments often encountered in hydraulic applications. The reinforcement technique used can significantly influence the hose's pressure rating and overall performance.

c. Hose Cover

hydraulic hose components

The outer layer of the hose, known as the cover, protects the inner components from external factors such as abrasion, weather, and chemicals. A good cover material is essential for ensuring the longevity of the hose. Common materials used for the cover include rubber and thermoplastics, chosen based on their resistance to environmental conditions.

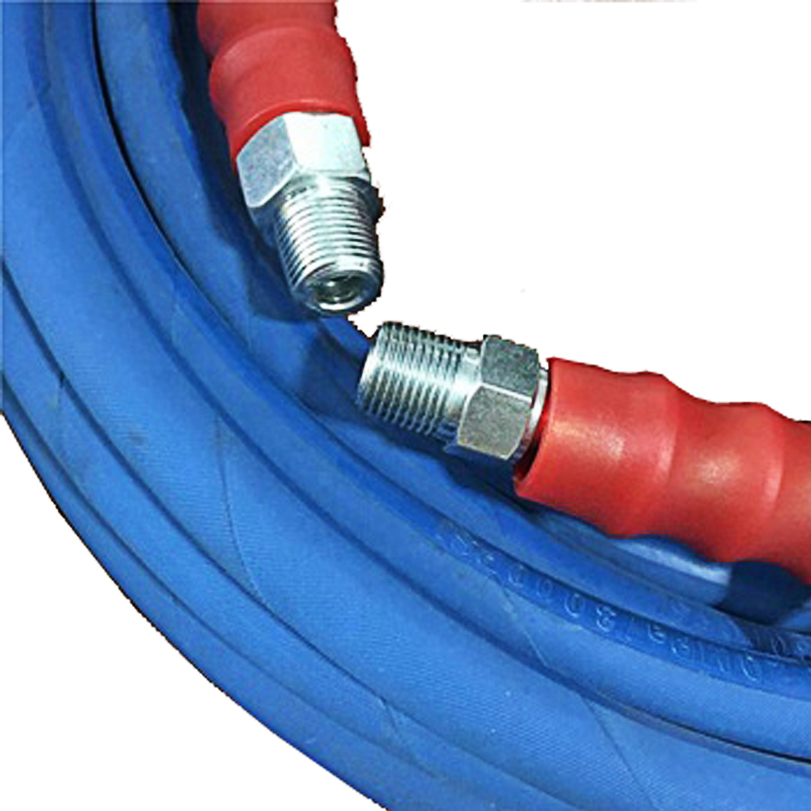

d. Fittings

Fittings are integral components that connect hoses to other machinery parts. They come in various shapes and sizes, including straight, elbow, and tee fittings. These connections must be secure to prevent leaks, and the selection of the right fitting is crucial for maintaining system integrity.

e. Couplings

Couplings serve as the link between the hydraulic hose and the hydraulic system. They are often used to connect hoses with different diameters or for easy disconnection and reconnection of hoses. Proper sealing within couplings is vital to prevent fluid leakage and maintain the efficiency of the hydraulic system.

3. Importance of Quality in Hydraulic Hose Components

The quality of hydraulic hose components can significantly impact the performance and safety of hydraulic systems. Poor-quality hoses can lead to leaks, bursts, and system failures, resulting in costly downtime and potential hazards to personnel and equipment. It is essential for operators to choose hoses and components that meet industry standards and specifications.

Regular inspections and maintenance of hydraulic hoses are also crucial. Signs of wear, such as cracks, bulges, or fraying, can indicate that a hose is nearing the end of its service life. Timely replacement of damaged components can prevent accidents and ensure the longevity of the hydraulic system.

4. Conclusion

Hydraulic hose components are essential elements that facilitate the seamless transfer of hydraulic fluid under pressure. Understanding the various parts, such as the hose tube, reinforcement layer, hose cover, fittings, and couplings, along with their functions, is vital for anyone working with hydraulic systems. By prioritizing quality and conducting regular maintenance, operators can enhance the performance of their hydraulic systems, ensuring safety and efficiency in their operations. Emphasizing the importance of these components will not only extend the life of the equipment but also contribute to the overall productivity of the industry. Whether in construction, manufacturing, or automotive applications, the role of hydraulic hoses and their components cannot be overstated.

-

High-Quality Distribution PTFE Hose for Industrial Flexibility

NewsJul.23,2025

-

Durable Pressure Washer Rubber Hose for Hot Water & High Flexibility

NewsJul.22,2025

-

Twin Hydraulic Hose for Efficient Fluid Transfer | Durable & Flexible

NewsJul.22,2025

-

Twin Hydraulic Hose | High Pressure & Durable

NewsJul.21,2025

-

Discount Hydraulic Hose Factories | Top Quality & Discounts

NewsJul.20,2025

-

EN856 4SP Hydraulic Hose - High Pressure & Durable

NewsJul.20,2025