335345435

يناير . 20, 2025 11:37 Back to list

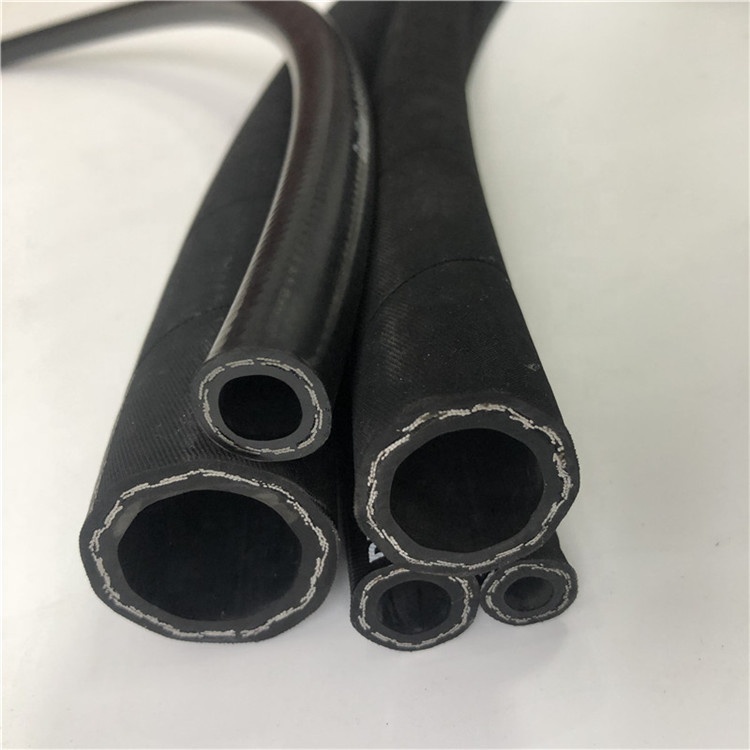

hydraulic hose wholesale

Fuel systems in vehicles and machinery rely on the quality and durability of hoses to ensure safe and efficient transport of gasoline. When considering a hose for gasoline, choosing a product that meets industry standards and offers reliability becomes crucial. Understanding the intricacies of gasoline hose selection not only enhances performance but also boosts the lifespan of your equipment.

When integrating a gasoline hose into your system, consider the fittings and connectors. Stainless steel clamps and brass fittings are preferred due to their corrosion-resistant properties. Ensuring a tight, secure connection minimizes the risk of leaks, maintaining the system's efficiency and safety. Proper installation is pivotal. Incorrect installation can lead to damaged hoses and compromised performance. Follow the manufacturer’s specifications regarding bending radius and installation guidelines. This attention to detail can prevent premature wear and safeguard against failure. Regular maintenance checks are recommended to prolong the life of a gasoline hose. Inspect hoses periodically for cracks, bulges, or dry rot, especially if the equipment is idle for extended periods. Be proactive in replacing hoses at the first sign of wear to avoid costly breakdowns and potential safety hazards. When purchasing a hose for gasoline, trust is essential. Sourcing from reputable manufacturers ensures that you're equipping your fuel system with a product that complies with stringent quality standards. Brands recognized for excellence in material science typically offer warranties and detailed specifications, further establishing credibility and fostering customer trust. In summary, a carefully selected gasoline hose is integral to the safety and effectiveness of your fuel system. By prioritizing high-quality materials, industry certifications, and precise installation, you not only protect your equipment but also uphold operational safety and efficiency. Recognizing the value of a reliable gasoline hose can translate into long-term savings, elevating overall system performance and establishing an authoritative stance in fuel management.

When integrating a gasoline hose into your system, consider the fittings and connectors. Stainless steel clamps and brass fittings are preferred due to their corrosion-resistant properties. Ensuring a tight, secure connection minimizes the risk of leaks, maintaining the system's efficiency and safety. Proper installation is pivotal. Incorrect installation can lead to damaged hoses and compromised performance. Follow the manufacturer’s specifications regarding bending radius and installation guidelines. This attention to detail can prevent premature wear and safeguard against failure. Regular maintenance checks are recommended to prolong the life of a gasoline hose. Inspect hoses periodically for cracks, bulges, or dry rot, especially if the equipment is idle for extended periods. Be proactive in replacing hoses at the first sign of wear to avoid costly breakdowns and potential safety hazards. When purchasing a hose for gasoline, trust is essential. Sourcing from reputable manufacturers ensures that you're equipping your fuel system with a product that complies with stringent quality standards. Brands recognized for excellence in material science typically offer warranties and detailed specifications, further establishing credibility and fostering customer trust. In summary, a carefully selected gasoline hose is integral to the safety and effectiveness of your fuel system. By prioritizing high-quality materials, industry certifications, and precise installation, you not only protect your equipment but also uphold operational safety and efficiency. Recognizing the value of a reliable gasoline hose can translate into long-term savings, elevating overall system performance and establishing an authoritative stance in fuel management.

Share

Latest news

-

Premium Distribution PTFE Hose: Flexible & Durable Solutions

NewsAug.22,2025

-

SAE 100 R3 / EN854 R3 Hydraulic Hose | Medium Pressure & Flexible

NewsAug.11,2025

-

EN856 4SP Hydraulic Hose: High-Pressure & Durable Solutions

NewsAug.11,2025

-

Premium Soft Rubber Tubing: Flexible & Durable Hose Solutions

NewsAug.10,2025

-

Premium Distribution PTFE Hose | Flexible & Durable Solutions

NewsAug.09,2025

-

Premium 38mm Hydraulic Hose Factories | Direct & Reliable

NewsAug.08,2025