335345435

ديسمبر . 11, 2024 09:59 Back to list

Aeroquip Teflon Hose Supplier for High-Performance Applications in Various Industries

Understanding Aeroquip Teflon Hose Manufacturing

Aeroquip is a name synonymous with high-performance fluid transfer solutions in various industries, including aerospace, automotive, and industrial applications. Among its diverse product portfolio, Aeroquip's Teflon hoses are particularly noteworthy due to their exceptional properties and versatile use cases. This article delves into the manufacturing process of Aeroquip Teflon hoses, their unique characteristics, and their applications across different sectors.

The Manufacturing Process

The manufacturing of Aeroquip Teflon hoses begins with the selection of high-quality polytetrafluoroethylene (PTFE) resin, a key ingredient known for its excellent chemical resistance and thermal stability. The process involves several stages

1. Extrusion The selected PTFE resin is heated and extruded into the desired hose shape. This step requires precision to ensure uniform thickness and integrity throughout the length of the hose.

2. Sintering After extrusion, the hoses undergo a sintering process, where they are heated at high temperatures in a controlled environment. This process enhances the material's mechanical properties and helps eliminate any residual solvents or additives.

3. Braiding To enhance strength and flexibility, Aeroquip employs a braiding technique. Resilient stainless steel or other materials are woven around the PTFE core, providing additional support and a higher burst pressure rating. This braiding process is essential, particularly for applications that require high pressure or exposed environments.

4. End Fitting Attachment The final stage involves attaching specialized end fittings tailored to specific applications. These fittings are designed to create leak-proof seals and accommodate various connection types, ranging from quick disconnects to rigid framing.

5. Quality Control Aeroquip places significant emphasis on quality assurance. Every batch of Teflon hoses undergoes rigorous testing for pressure resistance, flexibility, and chemical compatibility. This ensures that each product meets the high standards expected by customers across industries.

Unique Characteristics of Aeroquip Teflon Hoses

Aeroquip Teflon hoses boast several distinctive characteristics that make them highly advantageous in demanding environments

- Chemical Resistance The non-reactive nature of PTFE allows these hoses to handle a vast range of chemicals without degrading or altering the material properties. This makes them ideal for use in the chemical processing and pharmaceutical industries.

aeroquip teflon hose manufacturer

- High-Temperature Stability Teflon can withstand extreme temperatures, making Aeroquip Teflon hoses suitable for high-temperature applications such as in aerospace and automotive sectors where heat exposure is common

.- Low Friction The low friction coefficient of PTFE minimizes wear and tear, ensuring longevity and reliability in fluid transfer applications. This characteristic is particularly beneficial in dynamic systems where movement and flexibility are essential.

- Flexibility and Strength The braiding process used during manufacturing enhances the flexibility and tensile strength of the hoses. This allows them to bend and navigate around obstacles without kinking, which is critical for efficient system design.

Applications Across Industries

Aeroquip Teflon hoses find extensive application across a variety of industries due to their unique properties. Some notable applications include

- Aerospace In aerospace, these hoses are used for fuel and hydraulic fluid transfer systems, where safety and reliability are paramount. The ability to withstand extreme temperatures and pressures is critical in aviation applications.

- Automotive The automotive industry relies on Aeroquip Teflon hoses for high-performance fuel lines, brake systems, and power steering while ensuring compatibility with aggressive fluids.

- Chemical Processing Many chemical processing facilities utilize Teflon hoses for transferring corrosive chemicals and solvents, taking advantage of the material's chemical resistance.

- Food and Beverage In food processing, Teflon hoses are employed for conveying liquids that require strict adherence to hygiene standards, including dairy, wine, and other consumables.

- Pharmaceuticals The pharmaceutical industry’s need for sterile environments and compatibility with biopharmaceuticals makes Aeroquip Teflon hoses an ideal choice for product transfer and equipment cleaning processes.

Conclusion

Aeroquip's Teflon hose manufacturing embodies a commitment to quality, safety, and performance. By leveraging the superior properties of PTFE and employing robust manufacturing processes, Aeroquip delivers hoses that excel in some of the most stringent applications. Whether in the skies, on the roads, or within complex industrial systems, Aeroquip Teflon hoses continue to play a crucial role in ensuring safe and efficient fluid transfers.

-

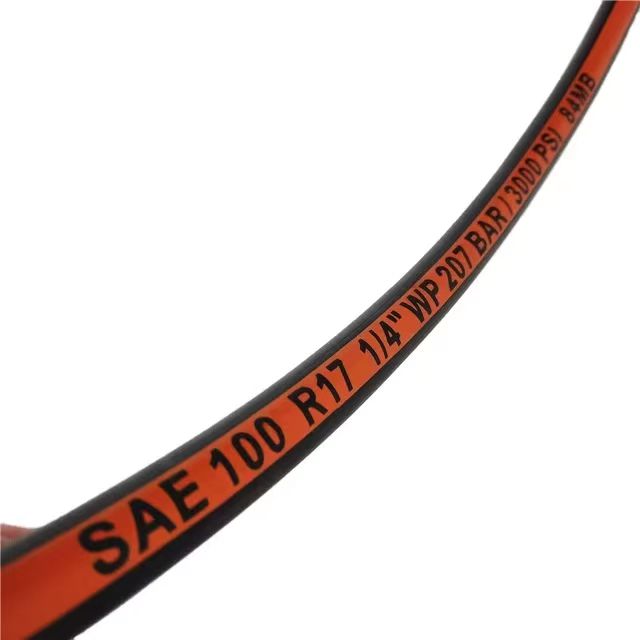

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025