335345435

ديسمبر . 16, 2024 05:34 Back to list

4sp hydraulic hose factory

The Excellence of 4SP Hydraulic Hose Factory A Benchmark in Industrial Performance

In the rapidly evolving world of industrial manufacturing, the quality and reliability of components play a crucial role in ensuring the seamless operation of machinery and systems. Among the various components used in hydraulic systems, hydraulic hoses stand out as vital elements that ensure the transfer of fluids and power. The 4SP hydraulic hose is recognized for its durability and efficiency, and the 4SP Hydraulic Hose Factory has established itself as a cornerstone in this niche market.

Understanding 4SP Hydraulic Hoses

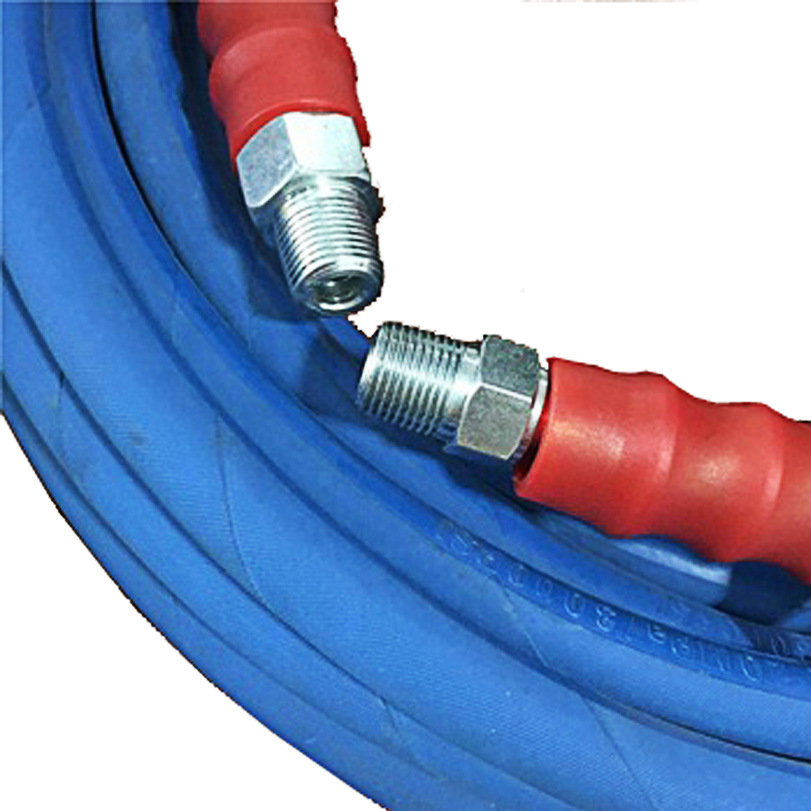

The term 4SP refers to a specific type of hydraulic hose construction that features four layers of steel wire reinforcement. This design not only enables the hose to withstand high pressures but also enhances its resistance to external damages. 4SP hydraulic hoses are typically used in demanding applications such as construction, agriculture, and various industrial sectors where reliable performance is essential. The hoses can handle pressures up to 420 bar, making them suitable for high-performance machines that require dependability under extreme working conditions.

Quality Manufacturing Processes

The 4SP Hydraulic Hose Factory employs cutting-edge technology and best-in-class manufacturing practices. The production process begins with the careful selection of raw materials. High-quality rubber materials, combined with specially treated steel wires, form the backbone of the hoses. The factory adheres to international standards such as ISO 9001, which ensures that every component of the production process is optimized for quality and consistency.

Once the raw materials arrive at the factory, they undergo rigorous testing before entering the production line. The manufacturing process involves the precise extrusion of rubber, followed by the layering of steel wires. Advanced machinery is utilized to ensure uniformity and adherence to specified dimensions. Additionally, a series of quality control checks are integrated at various stages of production to detect any anomalies early in the process.

Innovation and Research & Development

At the core of the 4SP Hydraulic Hose Factory’s success is its commitment to innovation. The factory boasts a dedicated research and development team that continuously explores new materials and designs to improve the performance and longevity of hydraulic hoses. By investing in R&D, the factory ensures that its products not only meet current industry standards but also anticipate future demands.

4sp hydraulic hose factory

The team conducts field tests and collects data to analyze performance under various operating conditions. This information is invaluable for refining existing products and developing new ones, thus maintaining the factory's competitive edge in the market.

Customer-Centric Approach

Understanding that customer satisfaction is paramount, the 4SP Hydraulic Hose Factory adopts a customer-centric approach in all its operations. The team collaborates closely with clients to understand their specific needs and challenges. This collaboration extends beyond mere sales; it involves providing specialized recommendations and solutions that enhance the clients' operational efficiency.

Furthermore, the factory places a strong emphasis on after-sales support. A dedicated customer service team is available to address any issues and provide assistance, ensuring that clients receive the full value of the products they purchase.

Sustainability Initiatives

In today’s environmentally conscious world, the 4SP Hydraulic Hose Factory recognizes the importance of sustainable practices. The factory is actively working towards minimizing waste and reducing its carbon footprint. By implementing energy-efficient processes and recycling materials whenever possible, the factory aims to contribute positively to the planet while maintaining high standards of product performance.

Conclusion

The 4SP Hydraulic Hose Factory exemplifies excellence in the manufacturing of hydraulic hoses. With its commitment to quality, innovation, customer satisfaction, and sustainability, the factory not only meets the demands of today but also paves the way for future advancements in the industry. As a leader in hydraulic solutions, it continues to set standards that inspire confidence and performance in every hose produced.

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

SAE 100 R17 Black Smooth Cover Hydraulic Hose

NewsMar.07,2025

-

steel wire braided hydraulic hose

NewsMar.07,2025